SERENA Tecnico GB R-04 del 04.04.17

00/ Per Bertani / Ma nuale Tecnico Serena / Serena

Pagina 17

6

CALIBRATION

SETTINGS -> CONFIGURA TIONS -> PASSWORD (hold START for 5 seconds till the menu appears) -

>CALIBRATION

Proceed with the calibration using UP / DOWN buttons

Press ESC to confirm

LOGO

LOGO

it is possible to change the pre-existing logo

SERIAL NUMBER

it is the serial number given to the machine

SOFTWARE VERSION

it is assigned by the provider and identifies a type of software

installed

CALIBRATION

the most important calibrations are PR -

T1, T2 and μs

INCREASE

BAR it is the maximum pressure during the vacuum peaks

TIMER FILLING

Min 000s Max 180s

It is the time in which the filling clean water pump is primed.

MAX VACUUM

(0300mb)

It is the maximum vacuum that the machine reaches more an x time. If does not go

under it the machine goes into alarm

DRY VACUUM

min 0500mb max 0900mb vacuum during drying phase

When it reaches the 0500mb it opens the valve of the bacteriological filter till 0900mb

VAPORIZER TEMPERATURE

min 140 ° C, max 150 ° C

The vaporizer is turned on until the beginning of sterilization. The pump that will

produce steam injects water between the two temperatures established.

121° CHAMBER IRON TEMPERATURE

min 120 ° C, max 125 ° C max

It is the metal temperature of the chamber during the 121° cycle

134° CHAMBER IRON TEMPERATURE

min 132 ° C, max 138 ° C max

It is the metal temperature of the chamber during the 134° cycle

IRON TEMPERATURE DRYING PHASE

It is the metal temperature of the chamber during the drying phase115°

EXTERNAL RESISTANCE TEMPERATURE

min. 140°C, max 145°C

It is the maximum temperature that the resistance can reach

RADIATOR TEMPERATURE

min. 080°C, max 085°C

It is the maximum temperature for condensing the steam

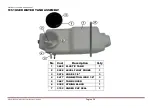

SERIAL NUMBER

SOFTWARE VERSION

CALIBRATION

INCREASE BAR

TEMP. REFILLING.

VACUUM MAX

VACUUM DRY

VAP. TEMPERATURE.

IRON CHAMBER TEMP. 121°

IRON CHAMBER TEMP 134°

IRON TEMP. DRYING PHASE

TEMP.EXT. RESISTANCE

RADIATOR TEMP.

ACTUATORS CHECK

The values shown are purely indicative and subject to change. Before the amendment contact the

manufacturer for updated data

7

RESET COUNTERS

The machine is equipped with counters that indicate the time when is important to change some

details, such as the door gasket and the bacteriological filter.

Once proceeded with the replacement of spare parts, it is important to reset the counter to zero by

performing the following operation -> MAINTENANCE:

- Position on the counter

- Simultaneously press the down and up arrow for a few seconds until it resets