© RESOL 11294 flo

wsol_d_d_he

.monen.ind

d

FlowSol D / D HE

19 |

Speed control

Min. speed

adjustment range (10) 30 ... 100%

factory setting (10) 30 %

D

Tset

adjustment range 2 ... 50 K

factory setting 10 K

rise

adjustment range 1 ... 20 K

factory setting 2 K

The relay is a semiconductor relay for pump speed control

of standard pumps. Relative pump speed is adapted in 10 %

steps to the current temperature difference between flow

and return. The parameter "

D

Tset“ is used as a set value

for pump speed control. Flow and return sensors are used

as reference sensors. The parameter „rise“ determines at

which change of temperature difference the speed will be

increased. In some cases, it is necessary to increase the

factory setting of the minimum pump speed (30%).

Furthermore, the controller keeps the flow rate within the

flow range of the station.

The

FlowSol

D HE with the high-efficiency pump controls

the pump speed down to 10% via the PWM output.

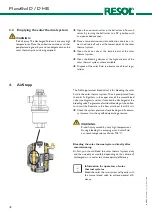

Defective sensors are shown in the status display. In the

next menu, the fault is indicated. For this purpose, briefly

press button 2.

Defective sensors

1,8 bar

Pressure

500 l/h

Flow rate

18,4 kW

Power

Error

S2 defect

P

V

broken

78,6 °C

92°C

34,5 °C

80%

broken

The defective sensor is indicated:

If the cable of a temperature sensor is broken, „broken“

is displayed, if the cable of a temperature sensor is short-

circuited, „short“ is displayed.

If a digital sensor is defective, „Defect“ is displayed.

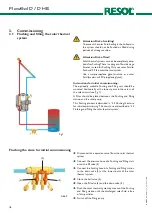

14. Messages

D

T-overrun function

D

T-overrun

selection „Yes“, „No“

factory setting „No“

off at

adjustment range 0,0 ... 20,0 K

factory setting 5 K

By means of this function, the pump continues to heat the

store even if the switch-off difference between collector

and store has been reached. The pump switches off, if the

adjusted "

D

T-overrun difference“ between flow and return

sensor has been underrun.

In this menu, the relay can be set into different modes:

• Off

• Auto

• Min. (minimum speed)

• Max. (maximum speed)

If "Off", "Min." or "Max." is selected, the

symbol will be

shown on the status display.

Relay mode

Relay mode

selection „Off“, „Auto“, „Min.“, „Max.“

factory setting „Auto“

1,8 bar

Pressure

500 l/h

Flow rate

18,4 kW

Power

Error

S2 defect

P

V

In the case of an error, a message is shown in the status

display. If there are several messages, only the message

having the highest priority is shown in the status display. All

other recently detected errors and messages respectively

are listed above the balance values (keep button 3 pressed

for 2 seconds).