EN

Resideo Technologies

8

Translation of original - EN1H-1375GE23 R1020

3.4

Function

The system comprises two multi-speed high-pressure rotary pumps with

inlet and outlet shut-off valves. They can be locked with padlocks against

unauthorised closing. They make it possible to disassemble the pumps or

the check valves without having to empty the pipeline system. The check

valve on the pumping side prevents liquid from backing up on the pump and

flowing backwards through it, and it relieves the floating ring seal.

The fully automatic Compact Booster Unit with compact design comprising:

•

vertical high-pressure pumps

•

electro-mechanical control unit to ensure the required supply pressure is

provided for the consumers

•

buffer tank with automatic refilling

construction and operation is according to DIN 1988, DIN 14462, EN 1717

and EN 13077.

3.4.3

Outlet side

On the outlet side there is a diaphragm expansion vessel as well as two

pressure switches and a pressure guage.

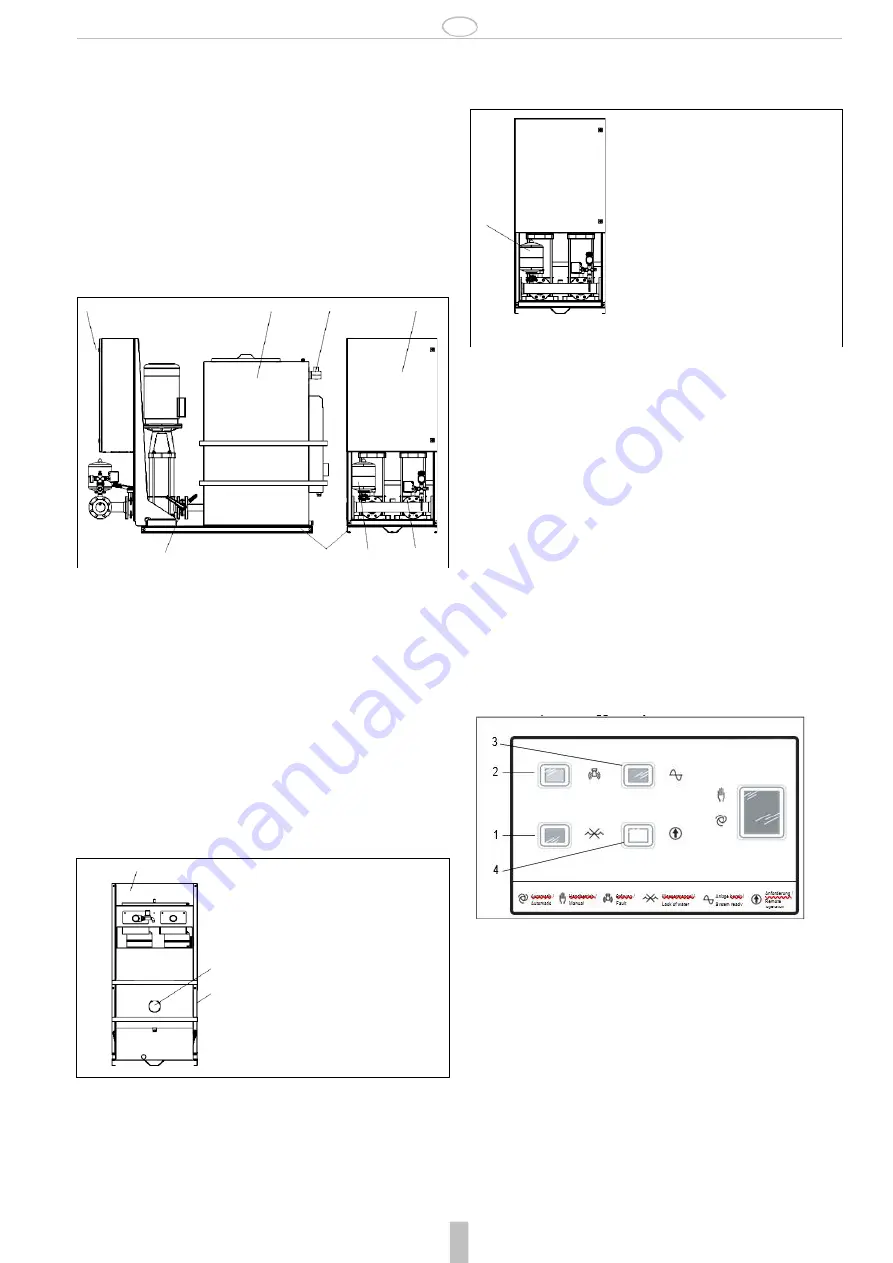

Figure 1:

1 Inlet

CBU145 Structure

2 Buffer tank

3.4.4

Switch cabinet

The switch cabinet is connected to the pump base frame and completely

wired with the Compact Booster Unit. Power supply for water level measure-

ment and solenoid valve is made possible via a plug connection to the

switch cabinet.

3.4.4.1

Automation

•

Electro-mechanical control unit

•

Timer for 24 hour functional operation and weekly flushing cycle

•

Manual/automatic switch

•

Phase monitor relays with rotation monitoring and phase failure protection

•

Protection against dry running and Motor protection switching, only as a

message during automatic operating mode

•

Terminal strip/clamps with labels for all connections

•

Easy starter

•

Remote on/off, protected against wire breakage and short circuit

3 Display

4 Switch cabinet

5 Pump

6 Base frame

7 Temperature monitor

8 Outlet shut-off valve

9 Bypass

3.4.1

Installation type

•

Fixed installation

3.4.2

Inlet side

On the inlet side there is a buffer tank with a float valve to refill water. Addi-

tionally the Compact Booster Unit has a solenoid valve for hygienic flushing

of the inlet pipe. In the buffer tank there are two float switches with which the

water level is measured and in the case of water shortage and overflow

messages are sent.

Figure 2:

CBU145 Inlet side

3.4.4.2

Messages given out by indicator lights

•

Red: Water shortage

•

Yellow: Malfunction

•

Green: Normal operation

•

White: Operation triggered by remote on/off

Figure 4:

CBU145 Indicator lights

1

Water shortage

2

Malfunction

3

normal operation

4

Operation triggered by remote

on/off

3.4.4.3

Messages sent via potential-free terminal clamps to, for

example, the central building control system

•

Water shortage

•

Switch to position manual/automatic

•

Buffer tank overflow

•

Remote actuation via remote on/off

•

Collective error message

•

Separation of potable water

1

Diaphragm expansion vessel

2

Pressure switch

3

Pressure gauge

1

Figure 3:

CBU145 Outlet side

3

2

1

4

8

6

5

7

1

1 Buffer tank

2

Float switch

3

Overflow

4

Siphon trap

3

4