889-2106-03

Model U-1400 Operations Manual Rev Apr 2020 Page

34

of 39

5.10

LOOP FAIL INDICATIONS

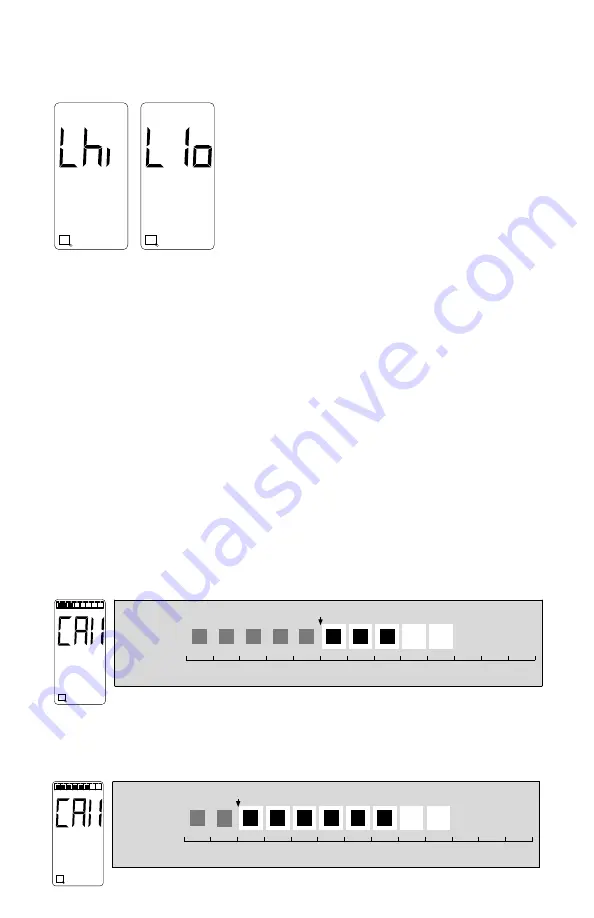

If the total inductance of a channel’s loop input network goes out of the

range specified for the detector, or rapidly changes by more than ±25%,

the loop input channel will enter the Fail-Safe mode and display

LOOP

FAIL

on the LCD. The type of loop failure will also be displayed as

L lo

(for -25% change or shorted loop conditions) or

L hi

(for +25% change

or open loop conditions). This will continue as long as the loop fault

exists. Fail-Safe mode generates a continuous call. At the time of a loop

failure, the loop input channel’s LED will begin to flash at a rate of three

flashes per second. The LED will continue this display pattern until the

channel is manually reset or power is removed.

If the loop self-heals, the

LOOP FAIL

message on the LCD will

extinguish and the loop input channel will resume operation in a normal

manner; except, the LED will continue the three flashes per second

display pattern, thus, providing an alert that a prior Loop Fail condition

has occurred. Each loop failure is counted and accumulated into the

Loop Fail Memory. The total number of loop failures for the loop input

channel (since the last power interruption or manual reset) is written into

the Loop Fail Memory and can be seen by stepping through the channel’s functions in Program Mode to the

LOOP

FAIL

display.

This is a useful tool to identify intermittent loop problems. If the count is extremely high for the period of time

observed, the problem is very likely a loose connection (check for loose connections at the terminal strip and bad

splices in the field). The Loop Fail Count is reset when power is removed from the detector. This prevents the

Loop Failure Count from moving to another loop if the detector is moved to a new location.

To view the Loop Fail Count, select the desired loop input channel using the

CHAN

pushbutton then repeatedly

press the

FUNC

pushbutton until the

LOOP FAIL

display is shown. The Loop Fail Count display is after the

Option displays. Pressing the

(UP) or

(DOWN) pushbutton while the Loop Fail Count is displayed, will

reset the count to zero.

5.11

SETTING SENSITIVITY USING THE BARGRAPH

The bargraph is a graphical representation of the relative change of inductance as seen by the detector loop input

channel; automatically taking into account sensitivity setting, loop geometry, configuration, lead-in length, etc.

The first bargraph segment represents the minimum inductance change (set by the sensitivity level) necessary for

the loop input channel to output a call. Each additional segment represents the inductance change in excess of the

next sensitivity threshold. Usually, the larger the vehicle detected, the more bargraph segments displayed, i.e. the

greater the -

∆

L/L. The bargraph can be used to select the proper sensitivity level.

The bargraph below shows the deflection (3 segments) of a vehicle with Sensitivity set to Level 5. The vehicle in

the loop zone is causing a change of inductance greater than 1.28% -

ΔL/Lor Sensitivity Level 3.

The bargraph below has the same vehicle in the loop zone causing the same inductance change as above. Because

the sensitivity setting was increased to Level 8, six segments are now displayed. If the bargraph displays 5 or 6

segments for a vehicle in the loop, the sensitivity has been set to the proper range.

+25% change

or open loop

condition.

-25% change

or shorted loop

condition.

LOOP FAIL

1

©

LOOP FAIL

1

©

SENSITIVITY 10 9 8 7 6 5 4 3 2 1

% of Inductance

0.01 0.02 0.04 0.08 0.16 0.32 0.64 1.28 2.56 5.12

The Bargraph is a window that adjusts to the sensitivity setting.

1

©

SENSITIVITY 10 9 8 7 6 5 4 3 2 1

% of Inductance

0.01 0.02 0.04 0.08 0.16 0.32 0.64 1.28 2.56 5.12

The Bargraph is a window that adjusts to the sensitivity setting.

©