Condensation of water

vapour

Since the maximum water vapour

volume increases when the air is

heated, the contained water va-

pour volume remains the same

however, this results in a reduction

of the relative humidity.

In contrast, when the air is cooled,

the capacity to absorb the maxi-

mum water vapour volume re-

duces, the water vapour volume

contained in the air remains the

same and the relative humidity

increases.

If the temperature falls further, the

capacity to absorb the maximum

water vapour volume is reduced

until it is equal to the contained

water vapour volume.

This temperature is called dew-

point temperature. When the air

is cooled below the dew-point

temperature, the contained water

vapour volume is larger than the

maximum water vapour volume.

Water vapour is discharged.

This condenses to water. The air is

relieved of moisture.

Examples of condensing are misted

windows in winter or misting of a

cold drinks bottle.

The higher the relative humidity,

the higher the dew-point tempera-

ture, which is easier to fall below.

Building materials or structures can

absorb substantial amounts of wa-

ter, e.g. bricks 90-190 l/m³, heavy

concrete 140-190 l/m³, lime-sand

bricks 180-270 l/m³.

The drying out of moist materials,

e.g. masonry, takes place as fol-

lows:

■

The contained

moisture moves

from the inside of

the material to its

surface.

■

Evaporation takes place on the

surface = transition as water va-

pour to the ambient air.

Temp.

Water vapour content in g/m

3

at a humidity of

°C

40%

60%

80%

100%

-5

1.3

1.9

2.6

3.3

+10

3.8

5.6

7.5

9.4

+15

5.1

7.7

10.2

12.8

+20

6.9

10.4

13.8

17.3

+25

9.2

13.8

18.4

23.0

+30

12.9

18.2

24.3

30.3

■

The air enriched with water

vapour continuously circulates

through the REMKO dehumidi-

fier. It is dehumidified and lea-

ves the unit at a slightly higher

temperature to absorb water

vapour from anew.

■

In this way, the moisture con-

tained in the material is gradu-

ally reduced.

The material dries!

The produced condensate is col-

lected in the unit and discharged.

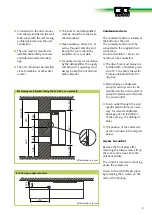

Verdampfer

Kondensator

°C

30

25

20

15

% r.F.

100

90

80

70

60

50

40

30

20

10

+

+

-

Lufttemperatur

Luftfeuchte

Verlauf

Luftrichtung

The air flow is cooled on its way through or via the evaporator to

below the dew point. The water vapour condenses and is collected

in a condensate trap and discharged.

Drying materials

Evaporator Condenser

Air temperature

Air flow direction

Air humidity

Trend

5