Before commissioning

After the tightness check has

been successfully completed,

connect the vacuum pump via the

pressure gauge station to the valve

connections on the outdoor unit

(see chapter "Tightness check")

and create a vacuum.

Perform the following checks

prior to commissioning the

unit for the first time and after

any interventions affecting the

refrigerant circuit. Record the

results in the commissioning

report:

■

Check of all refrigerant pipes

and valves with leak detection

spray or soapy water for leaks

and for inadvertent mix up of

suction and injection pipe, with

the unit at a standstill.

■

Check of all refrigerant pipes

and insulation for damage.

■

Check of all electrical

connections between indoor

unit and outdoor unit for

correct polarity.

■

Check that all fastenings,

mountings etc. are firm and at

the correct level.

Commissioning

Commissioning should only be

performed and documented by

specially trained personnel.

Observe the manuals for the

indoor unit and outdoor unit

when commissioning the

entire system.

NOTE

The system can be commissioned

once all the components have

been connected and checked.

A functional check should be

performed to verify its correct

function and identify any unusual

operational behaviour prior to

handing it over to the operator.

This check is dependent on the

installed indoor unit.

The procedures are specified in the

manual for the indoor unit being

commissioned.

Add refrigerant

The unit contains a basic quantity

of refrigerant.

In addition, an additional amount

of refrigerant must be added for

refrigerant pipe lengths exceeding

5 meters per circuit. Refer to the

following chart:

Note that the employed

refrigerant is always filled in

liquid form!

CAUTION

NOTE

Check the overheating to

determine the refrigerant fill

quantity.

Wear protective clothing when

handling refrigerant.

CAUTION

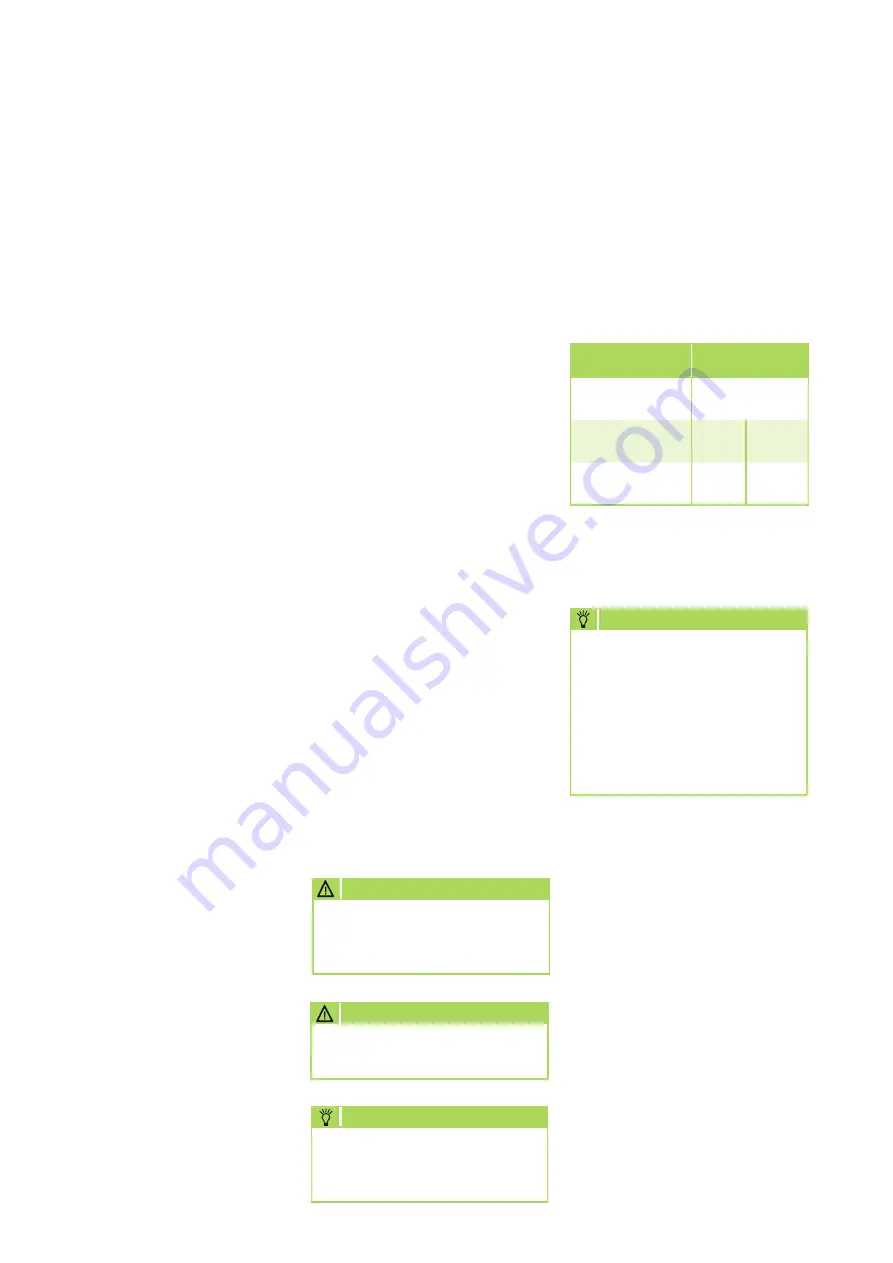

MVT

600 DC - 1050 DC

Basic pipe length

Additional

filling quantity

Up to and incl.

5 m

0 g/m

0 g/m

5 m to max. 15 m

per circuit

30 g/m

30 g/m

Condensate connection

and safe drainage

Condensate connection

If the temperature falls below the

dew point, condensation will form

on the finned condenser during

heating mode

.

Below the register is a collection

tray, which must be connected to

a drain.

■

The condensate line should

have a fall of min. 2 %.

This is the responsibility of the

customer.

If necessary, fit vapour diffusion

proof insulation.

■

When operating the unit at

outdoor temperatures below 4 °C,

make sure to route the condensate

line so that freezing is prevented.

The lower part of the housing

must also be kept frost free by the

user, in order to ensure permanent

draining of the condensate.

If necessary, fit a pipe heater.

■

After installation is complete,

check for unobstructed

condensation run off and

ensure that a permanent seal is

provided.

Safe drainage in the event of

leakage

Local regulations or environmental

laws, for example the German Water

Resource Act (WHG), can require

suitable precautions to protect

against uncontrolled drainage in

case of leakage to provide for safe

disposal of escaping air conditioning

fluid or hazardous media.

REMKO MVT

20