13

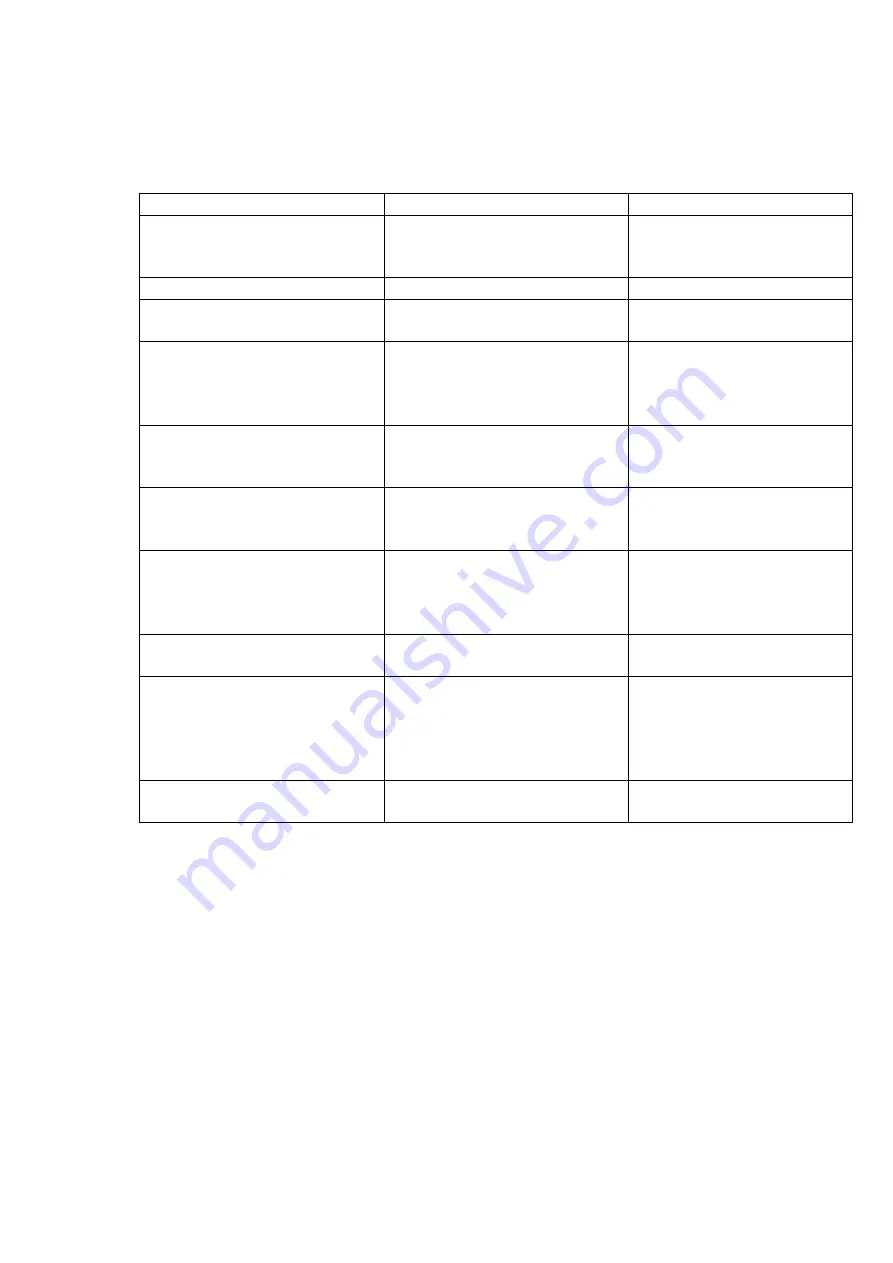

9. Possible malfunctions and the ways of their elimination

The list of possible malfunctions and the ways of their elimination are given in table 5.

Table 5

Name of faultiness

Possible reason

Method of elimination

Compressor’s productivity

slowdown

Distortion of the junctions’

density or air channels

Spot the leak, squeeze the

junctures, change the air

channels.

Air filter loading

Clean the filter element

Belt slip, due to insufficient

tension or fouling

Strain the belt, cleanse it.

Air leak from the pressostate’s

valve – constant “hissing”,

when the compressor is still

stopped.

Air leak because of wearing or

blocking of the check valve.

Unscrew the hexahedral

valve’s head, clean the sad-

dle or the seal disk, or

change them.

Motor overheating and engine

shutdown in the process of op-

eration.

Malfunction of the engine’s

ventilator

Check the ventilator, change

it if necessary.

Insufficient level of oil in the

compressor’s casing

Check the quality and the

level of oil, add some oil, if

necessary.

Continuous compressors opera-

tion with maximal pressure and

air consumption , which trig-

gers heat protection

Bring down the loading, air

consumption and pressure,

restart the compressor.

Compressor’s shutdown in the

process of operation

Feed network distortion

Check the feed network.

The compressor vibrates in the

process of operation, it drones,

after restart the compressor’s

engine doesn’t start, the engine

drones.

No tension in one of the feed

circuit’s phases.

Check and ensure the

feeding of the circuit.

Oil excess in compressed air

and receiver

Oil level in the casing is above

normal

Adjust it to the middle level.

In case of detection of other malfunctions it is necessary to consult the manufacturer.