19

Pul-Blast

AR pump system

Read this manual completely before operating: follow all safety instructions.

troubleshooting: excessive pressure drop

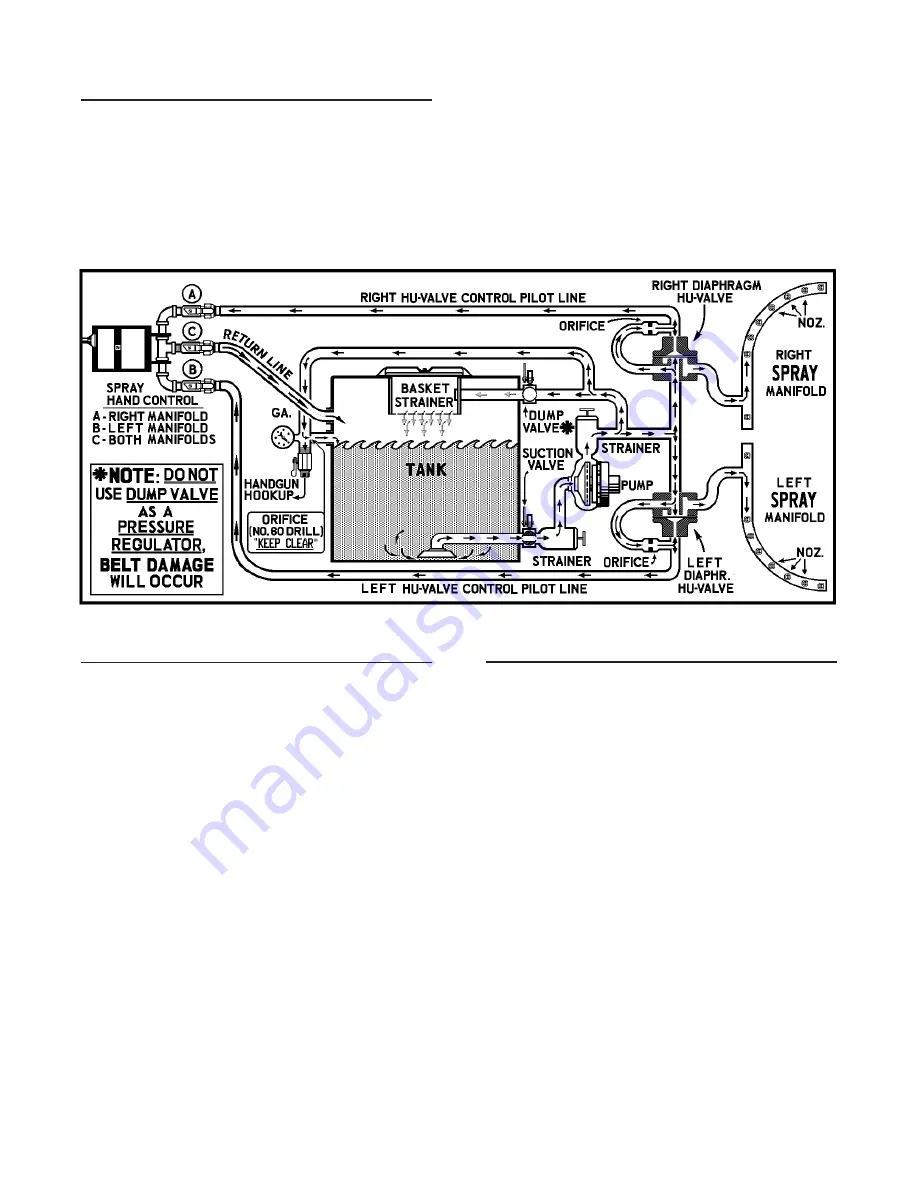

Check the dump valve. When spraying, the dump valve

must be completely closed. Using the dump valve to con

-

trol spray pressure will result in early belt failure.

Check the tension of the pump drive belt: see the pump

maintenance section of this manual.

Check the suction and discharge strainers- clean screens.

troubleshooting: spray manifold will not spray

Check that there is liquid in the tank.

Check that pressure is adequate on pressure gauge. If

not, refer to the pressure drop section, above.

Check the hand control pilot line (manual controls) for

crimping. Bleed off air at the handgun hookup valve.

Check the hand control pilot line (manual controls) for

blockage. Some chemicals can build up in the line or

react with the hose lining. If this is a problem, replace

the 3/8” lines with 1/2” hose.

NOTE: Rinse spray system daily.

Check the handset return line (manual controls) for

crimping or blockage.

Check the handset valves (manual controls) for blockage.

If you have Hu-valve electric controls, check the spool

rotation (see appropriate parts page for HVC block as

-

sembly illustration). If the spool rotates easily by hand

but not by the motor, check the wiring.

troubleshooting: spray manifold will not shut off

Check Hu-valve orifice and tube for blockage.

Check Hu-valve for ruptured diaphragm.

If you have Hu-valve electric controls, check the spool

rotation (see appropriate parts page for HVC block as

-

sembly illustration). If the spool rotates easily by hand

but not by the motor, check the wiring.

If you have Hu-valve electric controls and the unit

continues to spray with HVC spools in the OFF position,

a blockage caused the valve control to slip, see the HVC

block parts page for repair instructions.