US FLOOR / FLOOR

Minichiller inverter Duo

9

5

GENERAL CHARACTERISTICS

5.1 MODELLI

DISPONIBILI

•

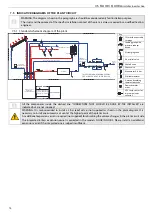

model FLOOR, 1-phase floor standing version, with technical water puffer tank in 190 L for DHW and technical water puffer

tank in 40 L for plant side

•

model FLOOR-S, 1-phase floor standing unit, with technical water puffer tank in 190 L for DHW equipped with solar coil and

technical water puffer tank in 40 L for plant side.

5.2 MODEL

FLOOR

As standard:

1)

Puffer for technical water of 190 liters for DHW (domestic hot water) and plant technical puffer of 40 liters, with

polyurethane coating of 50 mm thick.

2)

Circulator for the heat pump and the rapid preparer of high efficiency according to ErP directive up to values of EEI

≤

0.21.

3)

Pump circulator and rapid preparer of high efficiency according to ErP up to the values EEI

≤

0,21.

4)

Exchangers of the heat pump and of the DHW rapid producer in stainless steel AISI 304.

5)

Integrated Y filter.

6)

Tap of water charging/discharging for both DHW technical side and plant side.

7)

Automatic air vent valves mounted on the plant side and on the DHW technic side.

8)

Double manometer 6 bar to measure the water flow/load losses

9)

Double expansion vessels of 8 liters, one on the plant circuit side and the other on DHW technic side

10)

3 bar pressure relief valve to be connected with to a collecting system

11)

Flow switch for heat exchanger protection

12)

Flowmeter for managing the rapid production of DHW

13)

Single or three phase electric power supply

14)

Electric heater controller logic for plant side in integration and/or substitution

15)

Controller logic for boiler or similar source for both plant and DHW technical sides in integration and/or substitution of

the heat pump (digital contact)

16)

Integrated climatic system for plant

17)

Controller logic for plant remote sensor

18)

Integrated controller logic for double set-point of plant side

19)

Integrated controller logic for intelligent energy resources

20)

Integrable with HNSBox System

Accessories:

1)

Mixer’s controller logic for plant side in both heating and cooling operations. controller logic for solar integration.

Controller logic for relaunching circulator (secondary) plant side (optional kit, installed in the factory mod. GI2)

5.3 MODELS

FLOOR-S

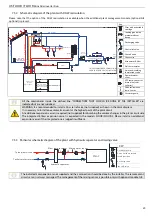

In addition to the above indicated characteristics:

1)

GI2 module for solar integration management logic. Management logic of the relaunching circulator (secondary) plant-

side. Mixing management logic for plant-side for both heating and cooling..

2)

Integration and management of solar DHW technical-side equipped with modulating High efficiency circulator according

to ERP Directive with EEi

≤

0.21.

3)

Flow regulator 2÷12 l/min

4)

Compact safety group with safety valve and pressure gauge.

5)

Integrated ball valve with thermometer and check valve.

6)

Temperature sensors DHW storage technical-side and solar collectors.

7)

Expansion vessel not included to be installed externally.

6

TECHNICAL CHARACTERISTICS

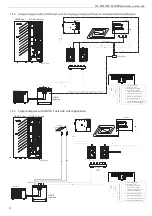

The reversible

heat pumps US series are designed for applications in residential and commercial areas, these units are extremely

versatile and can operate in heat pump mode with the ability of producing hot water at a temperature of 63°C using the electric

heaters for environmental heating and sanitary applications.

The new US system, which is the result of the evolution of the previous model, is the ideal solution for the total home climate

control (with the accessories Evo Touch (unscheduled) and HNS Box). For new or already existing house if equipped with a radiant

floor or fan coil as heating system, with feeding from electric power network and a renewable energy sources.

The INVERTER compressor with brushless DC motor technology, matched with electronic expansion valve, pump and variable

speed blower always with brushless motor, as well as the integrated circulators, optimize the power consumption and the

operation efficiency of the refrigerating components and of the entire system.

6.1

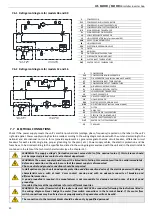

FRAME

All US units are made up of hot-galvanized thick sheet metal, painted with polyurethane powder enamels at 180°C to ensure the

best resistance against atmospheric agents. The frame is self-supporting with removable panels. All screws and rivets for outdoor

installations are in galvanized stainless steel. The indoor units also have a self-supporting structure made of galvanized steel with

removable painted panels.