Raytheon Anschütz GmbH

Postfach 1166

D -- 24100 Kiel

Germany

Tel +49--4 31--30 19--0

Fax +49--4 31--30 19--501

Email [email protected]

www.raytheon--anschuetz.de

3646/110--233.DOC010302

Edition:

May 20, 2005

Revision:

July 1, 2005

Revision:

Sept. 13, 2005

Revision:

Nov. 28, 2005

Revision:

Feb. 17, 2006

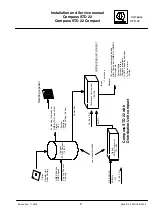

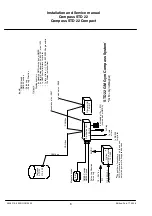

STD 22 Compact GYRO COMPASS

and

STD 22 GYRO COMPASS

Type 110--233

Installation and Service manual