4.1 General cabling guidance

Cable types and length

It is important to use cables of the appropriate type and length

• Unless otherwise stated use only standard cables of the correct

type, supplied by Raymarine.

• Ensure that any non-Raymarine cables are of the correct quality

and gauge. For example, longer power cable runs may require

larger wire gauges to minimize voltage drop along the run.

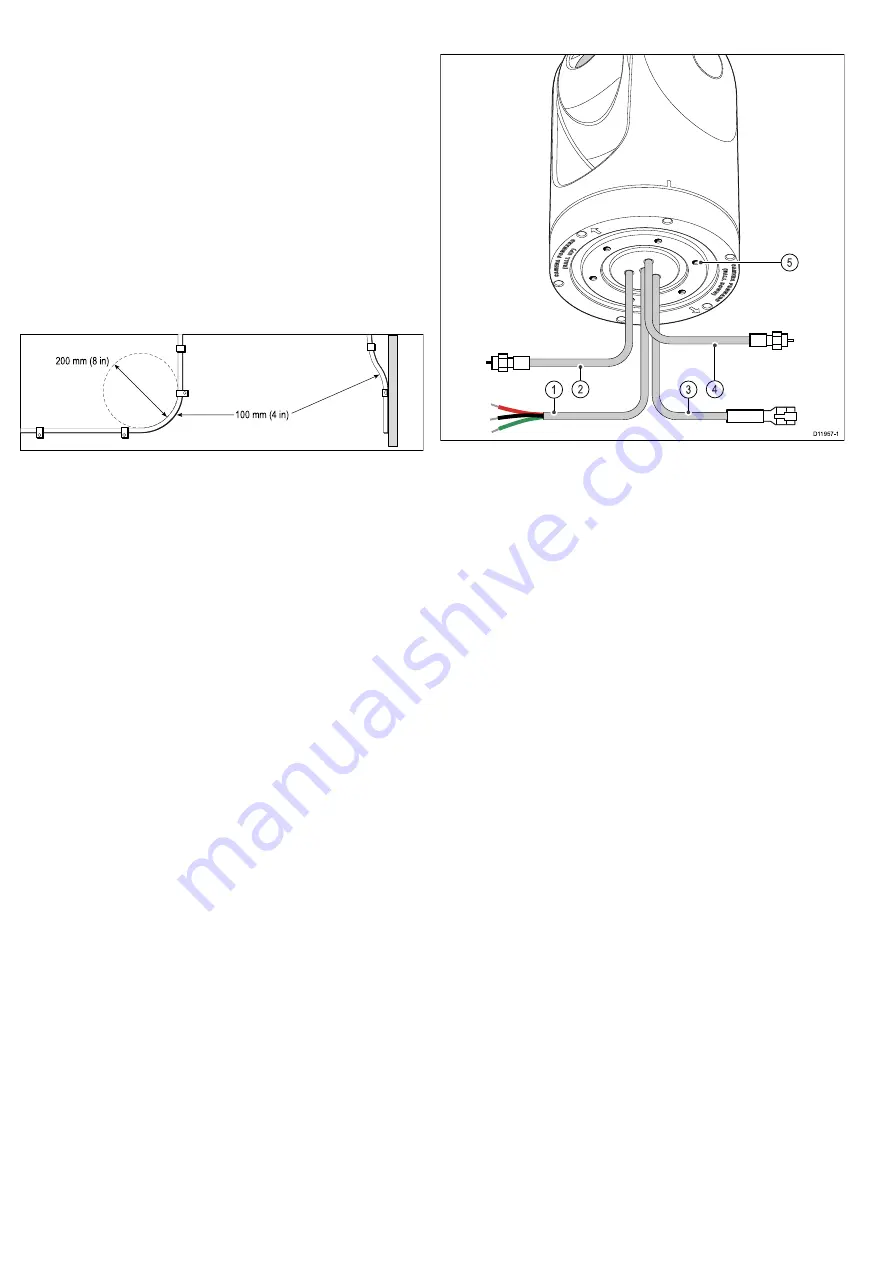

Routing cables

Cables must be routed correctly, to maximize performance and

prolong cable life.

• Do NOT bend cables excessively. Wherever possible, ensure a

minimum bend diameter of 200 mm (8 in) / minimum bend radius

of 100 mm (4 in).

100 mm (4 in)

200 mm (8 in)

• Protect all cables from physical damage and exposure to heat.

Use trunking or conduit where possible. Do NOT run cables

through bilges or doorways, or close to moving or hot objects.

• Secure cables in place using tie-wraps or lacing twine. Coil any

extra cable and tie it out of the way.

• Where a cable passes through an exposed bulkhead or deckhead,

use a suitable watertight feed-through.

• Do NOT run cables near to engines or fluorescent lights.

Always route data cables as far away as possible from:

• other equipment and cables,

• high current carrying ac and dc power lines,

• antennae.

Strain relief

Ensure adequate strain relief is provided. Protect connectors from

strain and ensure they will not pull out under extreme sea conditions.

Circuit isolation

Appropriate circuit isolation is required for installations using both

AC and DC current:

• Always use isolating transformers or a separate power-inverter

to run PC’s, processors, displays and other sensitive electronic

instruments or devices.

• Always use an isolating transformer with Weather FAX audio

cables.

• Always use an isolated power supply when using a 3rd party

audio amplifier.

• Always use an RS232/NMEA converter with optical isolation on

the signal lines.

• Always make sure that PC’s or other sensitive electronic devices

have a dedicated power circuit.

Cable shielding

Ensure that all data cables are properly shielded that the cable

shielding is intact (e.g. hasn’t been scraped off by being squeezed

through a tight area).

4.2 Connection overview

D11957-1

2

1

4

3

5

1.

Power and drain

2.

IR out – Thermal camera video

3.

SeaTalk

hs

– To Raymarine network switch or JCU

4.

VIS / IR out – Visible light and thermal video. (Dual payload

only, VIS / IR are switched using camera controls.)

5.

Low impedance ground connection

Connection care points:

• You must provide a low impedance chassis to ground connection,

this is made to any one of the chassis threaded fixing points and

is in addition to the drain-to-ground connection.

• The 450 mm (18in) cable tails should be routed to a dry area of

the vessel for connection. Alternatively you must ensure that all

connections are made water tight.

• Ensure that the VIS/IR feed is connected on dual payload models.

Without this connection the user will not be able to use the

camera controllers to switch between the thermal and low light

(visible) camera images.

Thermal camera cables

Cabling requirements for thermal cameras.

Camera to network switch

A network patch cable is required to connect the camera to the

network switch. The connection is made between the camera

cable tail and the network switch via the coupler (supplied with the

camera). Network patch cables are available in a variety of lengths.

Joystick Control Unit (JCU)

An Ethernet (with power) cable is used to connect the JCU. The JCU

is supplied with a 7.62 m (25 ft) Ethernet cable for this connection. If

you require a different length contact your dealer for suitable cables.

Power over Ethernet (PoE) injector to network switch

A network patch cable is required for connecting the PoE injector

to the network switch. Network patch cables are available in a

variety of lengths.

Video cables

Video cables are not supplied with the product. Please contact your

dealer for suitable cables and adaptors.

Raymarine recommends the use of a BNC terminated RG59 75ohm

(or better) coaxial cable.

20

T-Series

Summary of Contents for T303

Page 2: ......

Page 4: ......

Page 6: ...6 T Series...

Page 18: ...18 T Series...

Page 24: ...24 T Series...

Page 28: ...Thin panel mounting D11989 1 Thick panel mounting D11990 1 28 T Series...

Page 40: ...40 T Series...

Page 43: ......

Page 44: ...www raymarine com...