6.3 Power up and standby

When the breaker connecting power to the camera is switched on,

the camera will run a boot up sequence lasting for about 1 minute,

after which the camera will be in

Standby

mode.

In order for the camera to operate, you must bring the camera out

of standby mode using the camera controls.

Thermal camera standby

Standby mode can be used to temporarily suspend the thermal

camera's functions when the camera is not needed for a prolonged

period.

When in standby mode the camera:

• Does NOT provide a live video image.

• Moves the camera into its “stowed” (parked) position (lens facing

down into the camera base) to protect the camera optics.

• Engages its pan / tilt motors to hold the camera in place in rough

seas.

Note:

The “stowed” (parked) position can be configured using the

camera's setup menu.

Power menu

Menu item / Description

Settings / Operation

Assign JCU

Assigns the JCU to the camera.

JCU Stndby?

This option places the JCU in standby. The camera

and other controllers on the system are unaffected.

Camera Stndby?

With this option the camera moves to its stow

position and enters standby mode. The JCU

remains on and available to “wake” the camera.

System Off

This option places both the JCU and camera into

Standby mode.

Calibrate JCU

Use the “Calibrate JCU” function to calibrate the

JCU puck.

Follow the on screen instructions to calibrate the

puck:

•

Rotate CCW / CW

– requires you to rotate the

puck fully clockwise, then counter-clockwise.

then press the puck to continue.

Cancel

Exit the Power Menu.

Accessing the power menu

The power menu can be accessed by following the steps below.

Using the JCU

1. Press and hold the

Power

button on the JCU.

The JCU LCD will countdown from 3 to 0, after which the power

menu is displayed.

2. Use the JCU

Puck

to select the relevant power option.

3. Select

Cancel

to cancel the power menu.

Note:

The power menu is only displayed on the JCU's LCD

display.

6.4 Camera control

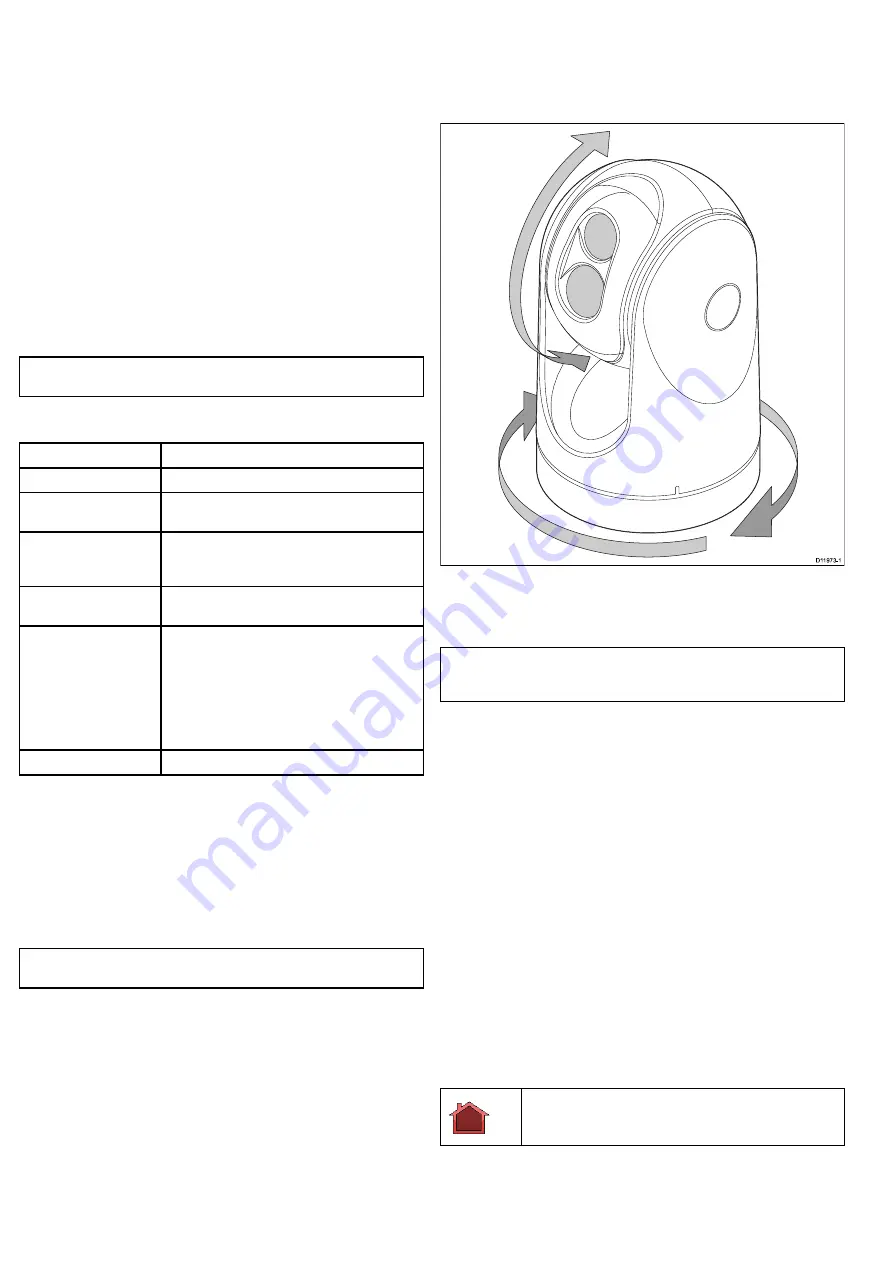

Pan, tilt and zoom

The camera controls allow for pan and tilt (elevation) of the camera,

as well as zoom (magnification) of the thermal image.

D11973-1

• Pan continuously through 360º.

• Tilt (elevate) to ±90º relative to the horizon.

• Zoom (magnify) the thermal camera image.

Note:

Stabilized variants of the T-Series thermal cameras include

a continuous zoom function, non-stabilized variants can switch

between x2 and x4 magnification.

Zooming the camera using the JCU

The JCU puck is used to control the zoom function of the thermal

camera, an icon will be displayed on-screen to indicate the current

zoom level.

With no zoom level selected:

1. Push the

Puck

in and hold for 1 second to turn on 2X zoom.

2. Push the

Puck

in and hold for 2 seconds to turn on 4X zoom.

3. Pull the

Puck

out to return to the previous zoom level.

Continuous zoom

The T470SC and T473SC have a continuous zoom color visible

light camera. The visible light camera will zoom to the same

magnification as the thermal camera. However, when the visible

light color camera is viewed the zoom can continue to a preset limit.

Thermal camera home position

The home position is a preset position for the camera.

The home position usually defines a useful reference point — for

example, straight ahead and level with the horizon. You can set the

home position as required and to return the camera to the home

position at any time.

The home icon appears on-screen momentarily when the

camera returns to the home position. The icon flashes when a

new home position is set.

32

T-Series

Summary of Contents for T303

Page 2: ......

Page 4: ......

Page 6: ...6 T Series...

Page 18: ...18 T Series...

Page 24: ...24 T Series...

Page 28: ...Thin panel mounting D11989 1 Thick panel mounting D11990 1 28 T Series...

Page 40: ...40 T Series...

Page 43: ......

Page 44: ...www raymarine com...