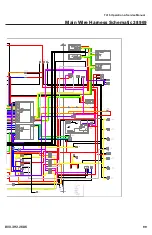

T415 Operation & Service Manual

800.392.2686

97

Maintenance

24

25

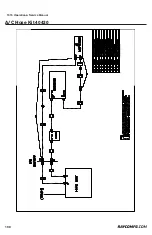

BLN-10197 • 520L0532 • April 2002

Series 45 Frame K and L Open Circuit Axial Piston Pumps

Service Manual

Minor repair

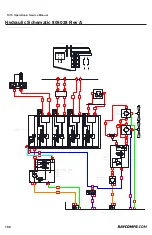

BLN-10197 • 520L0532 • April 2002

Series 45 Frame K and L Open Circuit Axial Piston Pumps

Service Manual

Minor repair

Reassembly

13. Install the PC spool, spherical end

first, into the PC bore. The PC spool is

the shorter of the two. Using a new

O-ring, install the plug (C103). Torque

to 11-14 N•m [8-10 lbf•ft].

14. Place the two PC springs onto the

spring guide and install into the PC

bore. Place a new O-ring onto the PC

adjustment screw and thread it into

the PC bore until flush, then make

another full turn. Install and torque

the set screw to 7-11 N•m [6-8 lbf•ft].

Note: For PC only controls, skip steps 15

and 16.

15. Install the LS spool, spherical end

first, into the LS bore. The LS spool is

the longer of the two. Using a new

O-ring, install the plug (C106). Torque

to 11-14 N•m [8-10 lbf•ft].

16. Place the two LS springs onto the

spring guide and install into the LS

bore. Place a new O-ring and back-

up rings onto the LS adjustment

screw and thread it into the LS bore

until flush, then make another full

turn. Install and torque the set screw

to 7-11 N•m [6-8 lbf•ft].

17. Using a new O-ring, install the

plug (C107). Torque to 11-14 N•m

[8-10 lbf•ft].

18. Using petroleum jelly to retain them,

install the three interface O-rings

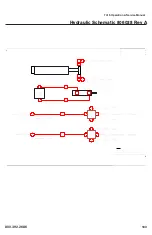

CONTROL

(continued)

C117

C118

6mm

C116

C117

C114

C115

C113

C200

C138

6mm

C136

C135

C134

C133

C132

C103A

C112

C106A

C106

3/16 in

11-14 N•m

[8-10 lbf•ft]

C103

3/16 in

11-14 N•m

[8-10 lbf•ft]

C300 (4pl.)

5mm

15-18 N•m

[11-13 lbf•ft]

C102 (2pl.)

4mm

7-11 N•m

[6-8 lbf•ft]

P101 667

C107A

C107

3/16 in

11-14 N•m

[8-10 lbf•ft]

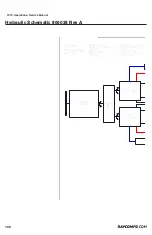

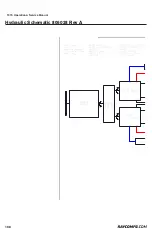

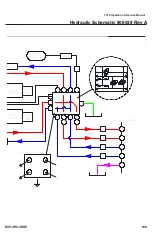

Control assembly

LS control shown; parts C106 and C112 through

C118 are not used on PC control

(C200) in the recesses on the control housing.

19. Install the control assembly onto the endcap using the four screws (C300). Torque to

15-18 N•m [11-13 lbf•ft]. Torque screws in a criss-cross pattern and re-torque the first

screw to ensure proper torque retention.

20. Check and adjust the control setting. See

Adjustments

, page 20.