Use and maintenance manual Aria

Pag.34

Rev.0 22/04/2022

EN

PROCEDURES FOR USE

⚠

If the chimney catches fire you must call the fire brigade immediately.

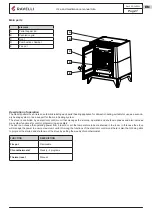

Checks prior to start-up

⚠

You have read and perfectly understood the contents of this instructions manual.

Before lighting the stove, you must ensure that:

•

the pellet tank is full;

•

the combustion chamber is clean;

•

the fire door and ash drawer seals are functioning properly;

•

the electrical plug is connected correctly;

•

all items that could burn (instructions, various adhesive labels) have been removed;

•

the brazier, if removable, is correctly positioned in its housing.

📌

During the first hours of use the paints used for the stove finish may release an unpleasant odour. You might also smell the

typical odour of metal parts subject to high temperatures. Make sure sufficient air circulation is guaranteed in the room. These

unavoidable inconveniences will disappear after the first hours of operation. To reduce your discomfort to a minimum, keep

the stove on for a few hours on low power and in the beginning, do not overload it, avoiding intense heating-cooling cycles

📌

At the initial start-up, the paint finishes drying and hardens. Accordingly, to avoid ruining it, we advise you not to touch the

stove’s painted surfaces at this time.

Auger loading

Before starting the stove for the first time, whenever the stove is in alarm “06 - Pellets finished”, and in any case whenever the hopper

has emptied completely, the initial feed screw loading is required. This phase serves to fill the pellet loading system so that, at the

time of ignition, the correct pellet loading takes place in the brazier.In the event that the feed screw operations are not carried out,

there may be stove ignition failures.

⚠

After loading the auger and before lighting the stove, always remember to empty the brazier and check that the brazier is

clean. Never empty the brazier inside the hopper.

⚠

After each maintenance operation, make sure that the brazier is positioned correctly in its seat.

⚠

In models with self-cleaning brazier it is not necessary to remove the pellets in the brazier: the pellets loaded are sufficient

for subsequent ignition.

User’s manual HANDHELD TOUCH RADIO

User’s manual HANDHELD TOUCH RADIO

Pag.22

Pag.23

Vers. 01 of:07.04.14

Vers. 01 of:07.04.14

Loading the auger

MENU

USER

SCREW FEEDING

SCREW FEEDING

CHRONOTHERMOSTAT

AIR-PELLET SET

STOVE STATE

USER

MANUFACTURER

ENGINEER

MENU

USER

MANUFACTURER

ENGINEER

USER

USER

COMFORT CLIMA

COMFORT CLIMA

COMFORT CLIMA

COMFORT CLIMA

ENABLE COMFORT

ENABLE COMFORT

ENABLE COMFORT

RESTART DELTA

RESTART DELTA

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

SHUTDOWN DELAY

ENABLE COMFORT

ENABLE COMFORT

COMFORT CLIMA DELTA

COMFORT CLIMA DELTA

RESTART DELTA

SHUTDOWN DELAY

SETTINGS

SCREW FEEDING

CHRONOTHERMOSTAT

AIR-PELLET SET

STOVE STATE

ALWAYS EMPTY THE BRAZIER BEFORE TURNING THE STOVE ON AND ALWAYS CHECK

THAT ALL NONE OF ITS HOLES IS CLOGGED NEVER EMPTY THE RBAZIER INSIDE THE HOPPER.

FIRE HAZARD.

Carry out this operation to facilitate stove’s first start operations; You should also check that you have introduced pellets

into the hopper and wait until the stove is in “SHUTDOWN” or “FINAL CLEANING” mode. The number expressed in sec-

onds indicates the rotation time of the infeed screw during the first loading cycle. Once this time has elapsed, the infeed

screw stops immediately and then pellets are emptied from the grate before turning on the equipment.

Below are given the steps for accessing the relative menu.

Press the key “access

menu” to access

the

MENU page

Press the key

“confirm”

to access the

USER page

At the end of the auger loading, the display shows 0 “and automatically switches to the USER menu page.

Press the key for several times until the Stand-by page is displayed.

Setting operating temperature and power:

Set the two values following the indications given in the chapter “Description of thr display”

Turning the device on

Keep the key ON/OFF pressed for a few seconds to turn on the stove.

Press CONFIRM to enable

the rotation of the auger

The appearance of the message “ADJUST THE RDS SYSTEM” indicates that the initial parameter testing procedure

and calibration has been unsuccessfully. This indication does not cause stove blockage (see the SIGNALLING POP UP

section).

On the display of the handheld set appears the following:

Press and hold the ON/OFF button to turn off the stove door, and reset any alarms triggered.

In case the infeed screw operations described avobe have not been executed, the stove may fail to turn on. In this case,

carry out the operations described above and empty the brazier and reset the alarm.

If the stove still fails to turn on, check that the grate is properly installed and perfectly adherent to the base, and also check that

there are no deposits that prevent the smooth passage of air to enable ignition. If the problem persists, contact the support ser

-

vice.

Sequence of ignition phases

SWITCH-ON- initial pellet loading phase;

WAIT FLAME - flame

development wait

phase;

FLAME PRESENT - flame stabilization

phase and reduction of combustible

inside the brazier;

What happens if the batteries are empty?

If the battery is discharged, within the

“drop” is shown a symbol that indicates

that the battery is empty, while maintain-

ing active the features of your device.

WORK - operation phase

described in

the dedicated chapter;

As soon as the level of the battery

prevents the radio communication the

handheld set displays on full screen the

picture of empty battery and all device

functions are locked until the batteries

are replaced

CONNECT AN EXTERNAL THERMOSTAT WITH A SIMPLE DRY CONTACT, THEREFORE, NOT POWERED. MORE-

OVER, WE RECOMMEND YOU USE A THERMOSTAT WITH A MINIMUM OFFSET OF 3°C IF YOU INTEND TO USE

THE COMFORT CLIMA FUNCTION.

Operating phases of the appliance

Modulation

During the work phase, the appliance should reach the room temperature set; when this condition is met, the stove switches to

MODULATION mode in which fuel consumption and ventilation are minimum.

If you wish to detect the ambient temperature by means of an external thermostat (optional), this must be connected to

the appropriate connector on the rear side of the stove; and you will have to activate the reading in “SETTINGS - EN -

ABLE THERMOSTAT.” On display appears the writing TON / TOFF based on thermostat request.

Comfort climate

The activation of this function enables the stove to reduce pellet consumption by activating the modulation phases, after the desired

temperature has been reached. Subsequently, the stove checks that the temperature is maintained steady for a preset time. If this

condition is met, it automatically switches off, and on display appears the writing ECO.

The stove turns on again when the temperature drops below the set threshold.

Below are given the steps for accessing the relative menu.

Press the key

“access menu” to

access

the

MENU page

Press the key

“confirm”

to access the

USER page

Once you have accessed the Climate Comfort menu, it is possible to operate on the 3 types of settings dedicated to the function:

Press the key for several times until the Stand-by page is displayed.

Press the key “selection” for

“selection”

to switch to the second page

of USER MENU and select

CLIMATE COMFORT.

Press the “menu access”

button to access the

MENU screen.

Press the “confirm”

button to access the

USER screen

Press the “confirm”

button to activate feed

screw rotation

Switching the appliance on and off

From the “Home” screen, it is possible to switch the stove on and off by keeping the ON / OFF button pressed on the device for a

few seconds. An acoustic signal will warn you that the appliance has switched on or off. In case it is not possible using your remote

control you can switch the appliance on / off using the appropriate button on the electronic board.

⚠

Do not switch off the heater by unplugging the plug from the wall socket.

📌

The appearance of the “SET RDS” message indicates that the initial parameter testing and calibration procedure was not

carried out correctly. This indication does not imply blocking the stove (see SIGNALING POP UP section).

MENU

USER

TECHNICIAN

PRODUCER

USER

LOADING AUGER

CHRONOTHERMOSTAT

SET AIR-PELLET

STOVE STATUS

LOADING AUGER