33

OPERATING

INSTRUCTIONS

NOTE:

Before using the tool, read the

instruction book carefully.

INTENDED USE

The machine is intended for impact drilling in

brick, concrete and stone as well as for drilling in

wood, metal and plastic.

1. INSTALLING THE AUXILIARY HANDLE

(SEE A)

Slide the handle onto the drill and rotate to the

desired working position. To clamp the auxiliary

handle rotates the handgrip clockwise. To loosen

the auxiliary handle rotates the handgrip anti-

clockwise. Always use the auxiliary handle.

2. INSTALLING THE DEPTH GAUGE (SEE A)

The depth gauge can be used to set a constant

depth to drill. To use the depth gauge, loosen the

handle by rotating the bottom section of handle

anti-clockwise. Insert the depth gauge through

hole in handle. Slide the depth gauge to required

depth and tighten fully.

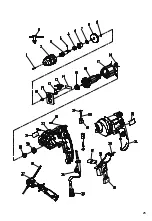

A

3. INSERTING A DRILL BIT INTO THE CHUCK

(SEE B)

To open the chuck jaws rotate the front section

of the chuck while holding the rear section.

Insert the drill bit between the chuck jaws and

rotate the front section in the opposite direction

while holding the rear section. Ensure that the

drill bit is in the center of the chuck jaws. Finally,

firmly rotate the two separate chuck sections in

opposite directions. Your drill bit is now locked in

the chuck.

WARNING: Before installing accessory,

remove plug from power supply. Do

not attempt to tighten drill bits (or any other

accessory) by gripping the front part of the

chuck and turning the tool on. Damage to the

chuck and personal injury may result.

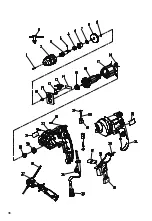

B

4. OPERATING THE ON/OFF SWITCH (SEEC)

Switching On and Off

Depress the on/off switch (6) to start the tool and

release it to stop your tool.

It is also a variable speed switch that delivers

higher speed and torque with increased trigger

pressure. Speed is controlled by the amount of

switch trigger depression.

Continuous use

Depress on/off switch (6) then lock-on button

(5), release on/off switch first and lock-on

button second. Your switch is now locked on

for continuous use. To switch off your tool just

depress and release the on/off switch.

C

5. FORWARD AND REVERSE ROTATION

CONTROL (SEE D, E)

For drilling and screw driving use forward rotation

marked “

” (lever is moved to the left). Only

use reverse rotation marked “

” (lever is

moved to the right) to remove screws or release

a jammed drill bit.

NOTE:

Never move the forward/reverse switch

whilst the drill in operation or the on/off switch is

locked as this will damage the drill.