WARNING !

When you are transferring hazardous fluids or the pump temperature

is over 60C, operator must take safety precautions to drain the fluid.

WARNING !

FIRE AND EXPLOSION HAZARD

If you are working with flammable fluids, be sure to take precautions

around the pump while cooling it. You must vent the exhaust to a safe

place

WARNING !

Diaphragm pumps are sold as pump unit only. Installing a control

device (if needed) is responsibility of the operator.

If the power supply of the pump (compressor) is stopped, the air

inlet to the pump must be cut off immediately. Otherwise when

compressor restarts, pump may start unexpectedly.

Manual operation:

If the power supply of the pump (compressor)

is stopped, operator must cut off the air feed to the pump

manually. The operator must be informed and warned about this.

Automatic operation:

If the power supply of the pump

(compressor) is stopped, control unit must cut off the air feed to

the pump automatically. Installing this system is the responsibility

of the operator or the owner.

6.0. PUMP OPERATION INSTRUCTIONS

IMPORTANT NOTE

The pump has a variable temperature resistance to the

transferred fluid. The temperature resistance of the

diaphragm, balls and ball seats defines the temperature

resistance of the pump.

6.1. Flush the pump before use.

Pump is tested with water. Flush the pump with a proper solvent before use if your fluid is affected by

water. Follow the instructions in

Starting and Adjusting the Pump.

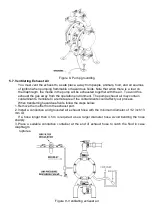

6.2 Starting and adjusting the pump

1- Check pump grounding before use.

2- Check fittings to be sure they are tight. Use a compatible liquid thread sealant (teflon, etc.) on

male threads. Tighten fluid inlet and outlet fittings securely.

3- Submerge the suction hose in the fluid.

Note: If the inlet fluid pressure is more than 25% of the outlet working pressure, ball check valves

will not close fast enough, result will be inefficient pump operation.

4- Place discharge hose in a suitable container.

5- Turn off the fluid drainage valve.

6- Turn the air regulator knob three quarters of a cycle clockwise, and open all bleed-type master air

valves.

7- Increase the air pressure slowly using the air regulator untill the pump primes. Set air regulator to

2 bar pressure. Operate the pump

slowly

until it is

fully loaded.

8- Working with thick fluids, operate the pump

very slowly

until it is fully loaded.

9- Pump is tested with water. If you need a clean pump in your process, flush the pump with suitable

fluid until it is fully clean. Then place the suction hose in the fluid container to be pumped.