R76 Series of Tire Changers

16

P/N 5900346 — Rev. C — Dec. 2019

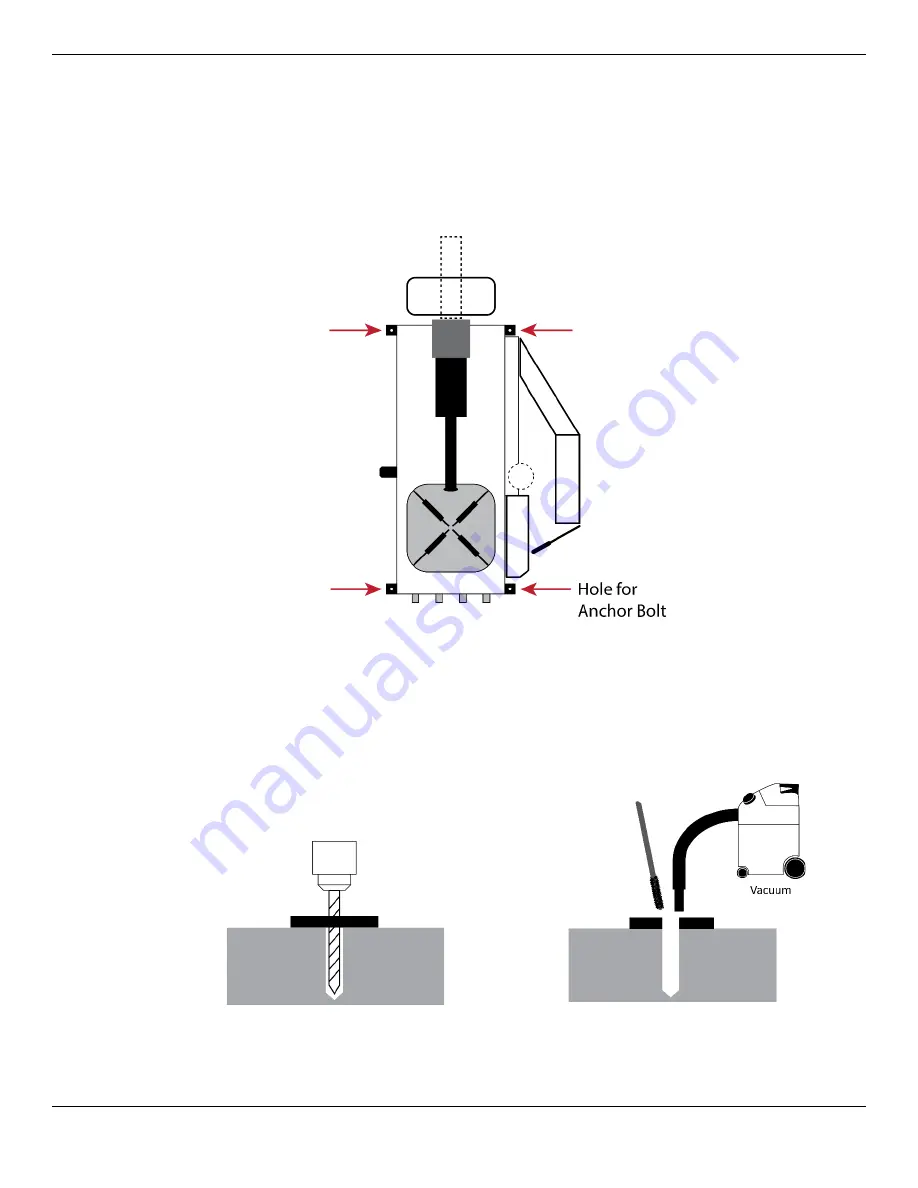

Anchoring the Tire Changer

The Tire Changer has holes for anchoring it into place; anchoring is optional.

Note

:

You are not required to anchor your Tire Changer. BendPak Ranger recommends doing

so, as the Tire Changer uses force at various times during the changing of a Tire.

Anchoring it ensures it will not move during operation.

The

.

5 in / 12.7 mm holes for anchoring are located in the four corners of the Tire Changer base.

The Anchor Bolts (sometimes called Wedge Anchors) mentioned in the following procedure are

not

supplied with the Tire Changer. You could, for example, use 3/8 in diameter by 3 in long Anchor Bolts

to secure the Tire Changer, drilling the hole approximately 2.5 in / 63.5 mm into the Concrete.

To anchor the Tire Changer

:

1.

Make sure the Tire Changer is in the desired location.

2.

Using the holes in the base as guides, drill a 2.5 in / 63.5 mm deep hole for each Anchor Bolt.

Use a drill bit that is the same diameter as the Anchor Bolt. So if you are using an 3/8 in diameter

Anchor Bolt, for example, use a 3/8 in diameter drill bit.

Go in straight; do not let the drill wobble. Use a carbide-tied drill bit (conforming to ANSI B212.15).

Summary of Contents for R76LT

Page 58: ...R76 Series of Tire Changers 58 P N 5900346 Rev C Dec 2019 Labels...

Page 59: ...R76 Series of Tire Changers 59 P N 5900346 Rev C Dec 2019...

Page 87: ...R76 Series of Tire Changers 87 P N 5900346 Rev C Dec 2019 Maintenance Log...

Page 88: ...1645 Lemonwood Drive Santa Paula CA 93060 USA 2019 BendPak Inc All rights reserved bendpak com...