SPECIFICATIONS / FEATURES

PROFESSIONAL:

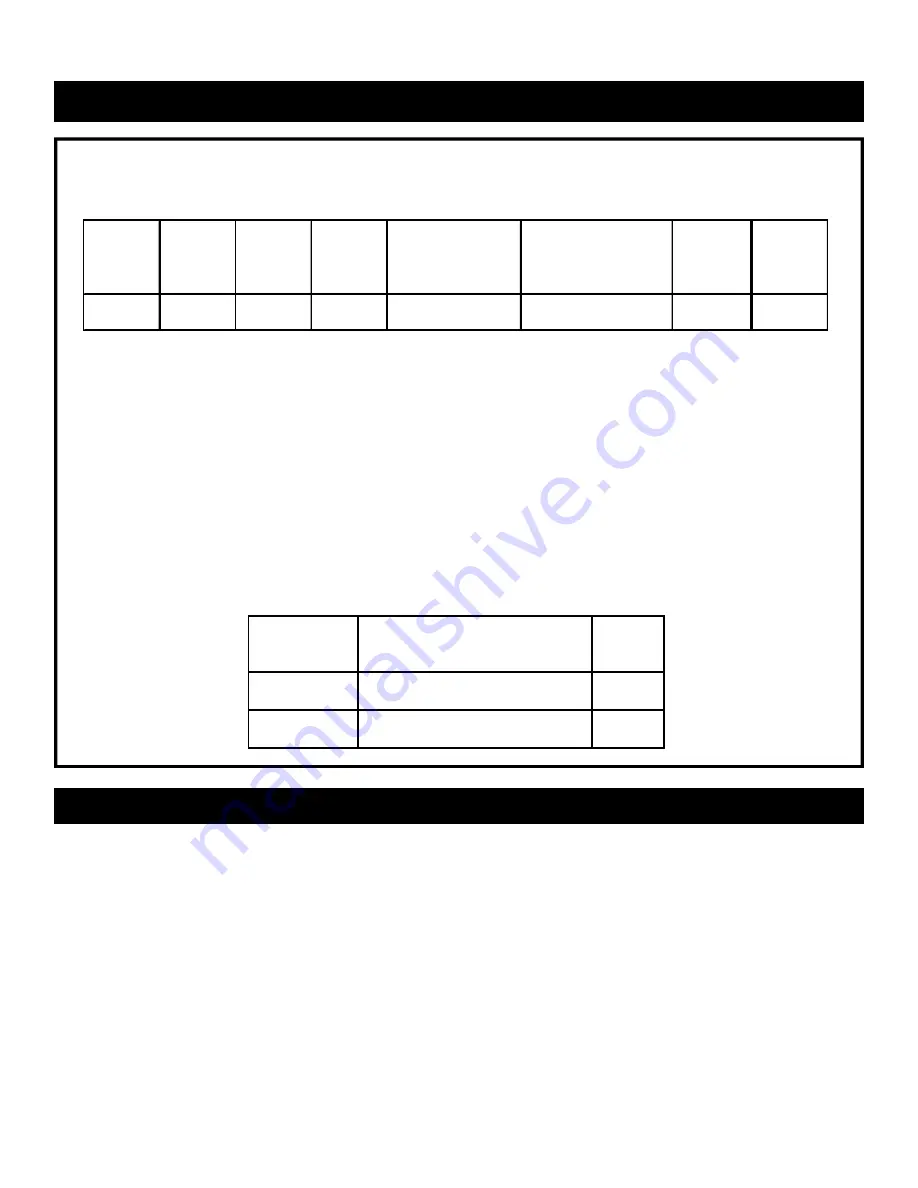

Models: R7580H-601 / R7580H-603 / R7580V-601 / R7580V-603

Motor

Max

PSI/BAR

Max CFM

@ 90

PSI/LM

Max CFM

@ 175

PSI/LM

Standard Voltage*

Pump Design

Speed

(RPM)

Tank

7.5hp

5.5 KW

175 PSI

12 BAR

26.5 CFM

750LM

25.5 CFM

723 LM

208-230V / 60 Hz

1 Phase

Tri-max™

3 Cylinder / 2 -Stage

1,150rpm

80 Gal.

304 L

Centrifugal unloader for no-load start

Mag Starter

Hardened steel disc valves

Precision balanced fan-type flywheel

Oversized tapered roller bearings

Forged ductile iron crankshaft

Forged aluminum alloy piston

Forged aluminum alloy connecting rods

Cast iron cylinders with deep-cool fins

Forced air aftercooler

Oil sight gauge

Totally enclosed belt guard

Forced air cooling

Pressure switch

Overload pressure safety valve

Pressure gauge and dual service valves

Oversize replaceable air filters

Auto start / stop

Model

Dimentions

Ship

Weight

R7580H-601

L 76" x H 44-1/2" x W 34-1/2"

L 1930mm x H 1130mm x W 876mm

650 Lbs

295 Kg

R7580V-601

L 37" x H 73" x W 34-1/2"

L 1930mm x H 1130mm x W 876mm

658 Lbs

298 Kg

* 3 phase and 50hz models are available upon request.

The standard features

ASSEMBLY INSTRUCTION

There is no assembly required. This compressor is completely pre-assembled at the factory.

Installation and Location:

Locate the compressor in a clean, dry and well ventilated area. The compressor should be located 12” to 18” from a

wall or any other obstruction that would interfere with the air flow through the fanbladed belt-wheel. Place the com-

pressor on a firm, level surface. The compressor is designed with heat dissipation fins which allow for proper cooling.

Keep the fins and other parts that collect dust and dirt clean. A clean compressor runs cooler and provides longer ser-

vice. Do not place rags, containers or other materials on top of the compressor which would obstruct ventilation open-

ings for proper compressor operating temperature.

For Vertical Type Only:

For permanent installation, the compressor should be bolted to the floor through holes pro-

vided in the compressor feet. Shims must be used to level the compressor before bolting it to the floor. Severe vibra-

tion will result when the compressor is bolted down tightly and the feet are not level. This can lead to welds cracking

or fatigue failure of the air receiver.