9

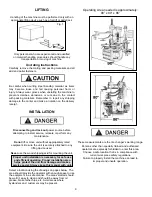

LIFTING

Handling of the machine must be performed only with an

appropriate lifting device such as a forklift or pallet jack.

Only personnel who are experienced and qualified

on material handling procedures should handle any

transportation or moving of machine.

Uncrating Instructions

Carefully remove the crating and packing materials and all

skid and pallet fasteners.

Be careful when cutting steel banding material as items

may become loose and fall causing personal harm or

injury. Always wear gloves when uncrating the machine to

prevent scratches, abrasions, or cuts due to the contact

with packing materials. Remember to report any shipping

damage to the carrier and make a notation on the delivery

receipt .

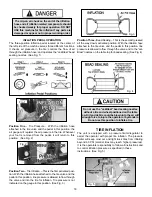

INSTALLATION

Disconnect tag and lock out

power source before

attempting to install, service, relocate or perform any

maintenance.

Do not

lift or move unit without appropriately rated

equipment. Be sure the unit is securely attached to any

lifting device used.

Never

use the wood shipping skid for mounting the unit.

Select a location using the drawings on pages below. The

area should provide the operator with enough space to use

the equipment in a safe manner. The area selected should

be well lit, easy to clean and should be away from oil,

grease, brake lathe chips, etc. Avoid areas where

bystanders and customers may be present.

Operating Area needed is approximately:

90” x 80” x 86”

These measurements are the tire changer’s working range.

Persons other than specially trained and authorized

operators are expressly forbidden to enter this area.

Choose a safe location that is in compliance with

current work place safety regulations.

Failure to properly install the machine can lead to

improper and unsafe operation.

Fig. 1

Proper unit installation is necessary for safe use

and efficient operation. Proper installation also

helps protect the unit from damage and makes

service easier. Always keep this manual with unit.

Summary of Contents for R23

Page 25: ...25...

Page 26: ...26 R23 00 00 REVISION A 22 Tire changer...

Page 44: ...44 3 7 3 5 66 0 PL330B 00 00 REVISION A 04...