17

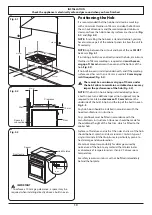

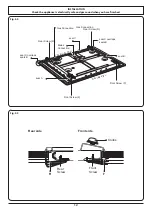

INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

Safety Information

Ensure that the gas supply pipe is never able to touch

moveable parts of the built-in cabinet (e.g. drawers). It must

not pass through compartments that could be used for

storage purposes.

When using a flexible hose, it is essential to comply with the

following instructions:

•

No part of the pipe must be able to touch parts the

temperature of which exceeds 75°C

•

The pipe must not be pulled or twisted, throttled or

tightly bent.

•

It must not come into contact with sharp edges or

corners.

•

It must be easy to inspect the entire pipe length in order

to check its state of wear.

•

The pipe must be replaced within the date stamped on

the pipe itself.

If in doubt, contact your supplier.

After completing the gas connection check the hotplate is

gas sound with a pressure test.

Pressure Testing

The gas pressure can be measured at one of the hotplate

burner injectors (not the Wok burner). Lift off a burner head.

Fit the pressure gauge to the injector. Turn on and light one

of the other hotplate burners. Turn on and push in the control

knob for the burner with the pressure gauge fitted to let gas

through.

Refer to the “Connections” table in the “Technical Data” for

pressure settings

Turn off the burners. Reassemble burner top, making sure it is

reassembled in the correct way on the burner body.

Summary of Contents for ECL90HPNGFBL/BL

Page 1: ...ECL90HPNGFBL BL Gas on Glass Hob User Guide Installation Service Instructions U111054 02A...

Page 2: ......

Page 4: ......

Page 27: ...23 NOTE...