15

SERVICING

IT IS ESSENTIAL THAT THE BOILER IS CHECKED ANNUALLY TO VALIDATE THE WARRANTY

Checks must include the electrical connections and inhibitor concentration.

Before any servicing or maintenance is carried out on the system, ensure that the electrical supply has been disconnected first. Care must also be

taken as the water may be scalding hot and at a high pressure.

Check the main electrical power connections are tight. Loose connections can cause a fire.

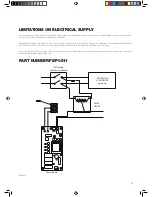

PART LOCATIONS

Fuse F1 is found near the top of the main Power Board assembly, See fig 8 (page 17).

The manual reset high limit cut out switches CN12 are left hand side and also the left hand side of the heatsink block, See fig 1 (page 4).

The control board assembly is mounted on the front, and plugged into the main power board at PL1

To change the main power board, follow ‘Replacing the Main Power Board’ procedure.

Each of the main electrical elements should have a resistance of approximately 19 ohms for a 3kW Element and 28 ohms for a 2kW element terminal

to terminal, (black to black, grey to grey, blue to blue and green to green) and an insulation resistance greater than 2 Meg ohms between terminal and

case. If the elements are open circuit terminal to terminal, or have short circuit insulation resistance terminal to case, the individual element needs to

be replaced (page 16).

FAULT FINDING

1. Should the RED FAULT indicator illuminate the fault can be traced using the fault code indicated by the flashing HEAT

indicator. The HEAT (green bar graph indicator) will flash a number of times and then pause, the fault can them be determined from the fault tracing

charts on pages 16,17 & 18.

2. Should the FAULT indicator flash then there is possibly a fault in one of the heater elements, this will not cause the unit to stop operating but

serves as a warning that one or more of the elements are not working. The unit’s heat output will be reduced The Boiler must NOT be operated if it is

known to have a fault.

FAULT RESET PROCEDURE

There are 3 steps to re-set a tripped condition:

1 - Switch Main Power Supply and Demand OFF.

2 - Correct the fault, check the system is full of water and set to the correct pressure (pressurized systems) and there is a good flow of water (i.e. all

the valves are open).

3 - Switch the supply back ON.