N-Series

3D Printer

/ Quick Start Guide

B

Hardware Installation

(continued)

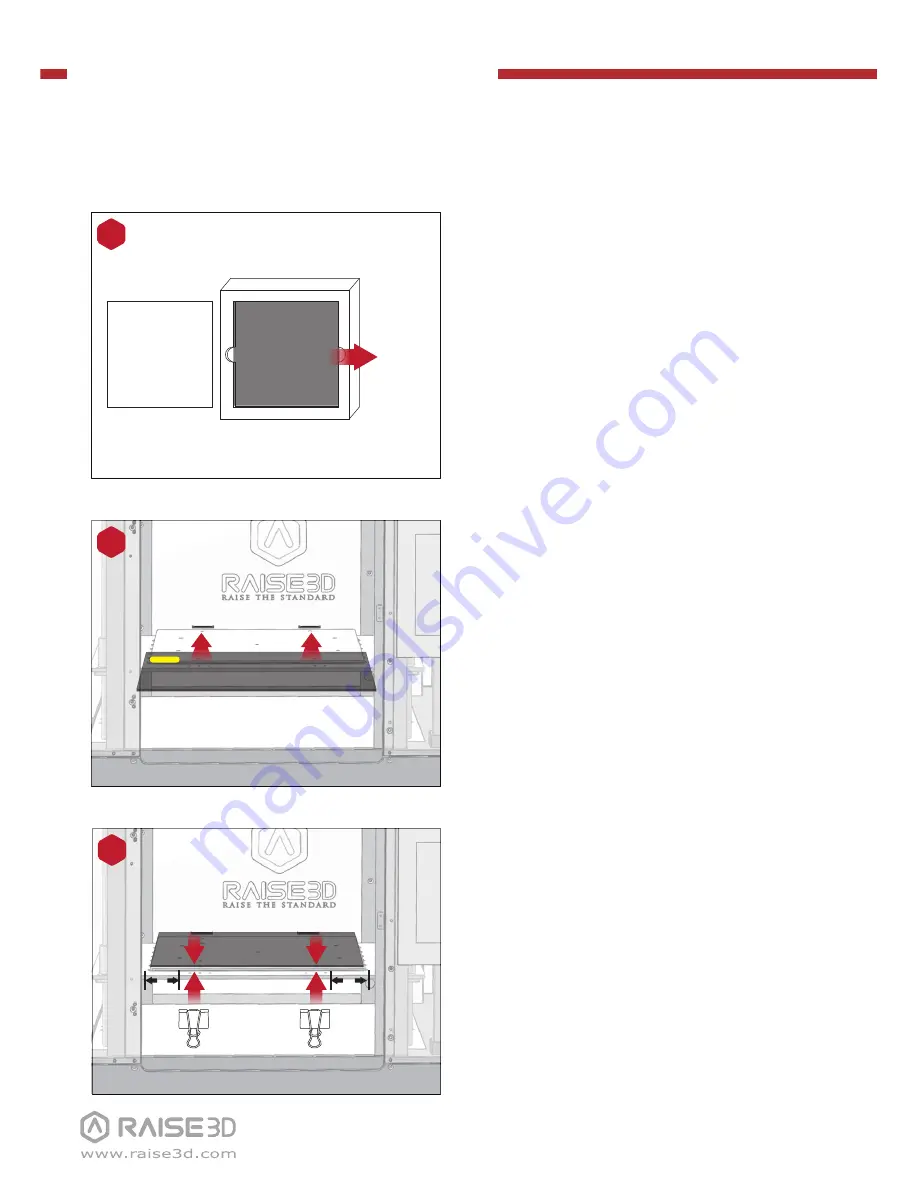

Remove the remaining build plate clips

from the accessory box and secure them

to the glass and heated bed plate.

NOTE:

The best distance between the glass clip

and the edge of print platform is 5cm.

10

5cm

5cm

Gently slide the glass plate. Make sure it

snaps into the build plate clamps at the

back.

NOTE:

Place the surface which posted with

BuildTak upwards, while the yellow label is at the

back left corner. Make sure it snaps into the build

plate clamps in this way.

9

Remove the glass build plate from the

protective foam.

8

Protective Foam

Cover

Build Plate

Remove!