14

www.raider.bg

• The machine must be set up so that it stands firmly, i.e. it must be securely screwed to a

work bench or similar. • All covers and safety devices have to be properly fitted before the

equipment is switched on. • The grinding and polishing wheel must rotate freely. • Check that

the voltage on the rating plate is the same as your supply voltage before you connect the

equipment to the power supply.

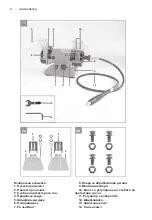

3.1 Fitting the spark refl ector (Fig. 2-4 / Item 3) Fit the spark refl ector (3) to the double

wheel grinder using the adjusting screw (10).

3.2 Adjusting the spark refl ector (Fig. 5 / Item 3) • Adjust the spark deflector (3) using the

adjusting screw (10) so that the distance between the dry grinding wheel (5) and the spark

deflector (3) is as small as possible and certainly does not exceed 2 mm. • Adjust the spark

deflector (3) periodically to compensate for wear on the wheel.

3.3 Fitting the workpiece supports (Fig. 6 / Item 8)

Secure the workpiece supports (8) to the double wheel grinder using the star screw (7).

3.4 Adjusting the workpiece supports (Fig. 7 / Item 8) • Adjust the workpiece supports (8)

using the star screws (7) so that the distance between the dry grinding wheel (5) and the

workpiece support (8) is as small as possible and certainly does not exceed 2 mm. • Adjust

the workpiece supports (8) periodically to compensate for wear on the dry grinding wheel (5).

3.5. Changing the wheels (Fig. 8-9)

Remove the 3 screws (A) holding the side section of the safety hood (B) and remove the

safety hood. Slacken the nut (D) (Important: The grinding wheel on the left is fastened with a

lefthanded thread and the grinding wheel on the right with a right-handed thread) by holding

the nut of the grinding wheel mount on the opposite side. Then remove the fl ange (C) and

replace the grinding wheel (5). To assemble, proceed in the reverse order. The grinding wheel

is mounted with the help of a rag. Mount the fl ange (C) and the nut (D) on the shaft and hold

steady with the help of a rag when you tighten the nut (D).

3.6 Installing the fl exible shaft (Fig. 10) • Insert the internal axle (a) of the flexible shaft (12)

into the guide shaft of the equipment. • Secure the fastening nut of the flexible shaft to the

equipment thread by hand (left-hand thread).

Important!

When you work with the fl exible shaft (12), the safety glass (2) must be placed right up

against the workpiece support (8) in order to prevent uncontrolled touching of the wheels.

3.7 Inserting the various tools into the fl exible shaft (Fig. 11)

1. Press the supplied locking pin (13) into the hole in the fl exible shaft (12) and turn the

shaft until the pin latches in place.

2. Now undo the collet chuck nut.

3. Insert the required tool into the sleeve as far as the stop and screw the collet chuck nut

tight.

4. Operation

4.1 On/Off switch (1)

To switch on the equipment set the On/Off switch (1) to position I.

Move the On/Off switch (1) to position 0 to switch off the equipment.

Important!

When you are not working with the fl exible shaft (12), it is not allowed to be mounted on

the equipment because it could then fl y around out of control.

After switching on, wait for the equipment to reach its maximum speed of rotation. Only

then should you begin with the grinding.

4.2. Speed selector (Fig. 1)

The required speed can be set with the speed control (11).

4.2.1 Speed of the fl exible shaft

The correct speed depends on the tool used and the type of material being processed.

4.3. Information on speed settings • Small cutters/grinding pins: High speed • Large cutters/

grinding pins: Low speed

4.4. Work practice • Exert only moderate pressure on the workpiece so that it can be

Summary of Contents for RD-BG06

Page 52: ...52 www raider bg Exploded drawing of Bench Grinder RD BG06 ...

Page 62: ...62 www raider bg ...

Page 67: ...67 ...