8. Set-Up & Operation

- Continued

Cooled Carousel 12 Plus Reaction Station

Page 10

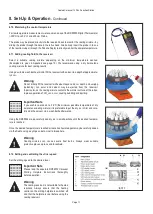

8.7. Place Assembled Capped Tube in Carousel

Place the capped tube into the assembled Carousel at the required location, push the Easy-

On Cap onto the connector pin, until the Reaction Tube is fully located in the base.

The stainless steel Gas Outlets feature an upper and lower replaceable Nitrile o-ring as

standard with an optional Viton replacement. These O-rings may be subject to chemical

attack and will require periodic replacement.

RR91060 Nitrile O-Rings 4mm Gas Outlet - Bottom, pk 50

RR91061 Nitrile O-Rings 3mm Gas Outlet - Top, pk 50

RR91062 Viton O-Rings 4mm Gas Outlet - Bottom, pk 50

RR91063 Viton O-Rings 3mm Gas Outlet - Top, pk 50

8.8. Connect Reflux Coolant Supply

For cooled reactions, reflux cooling is not required. Please refer to the Carousel 12 Plus

Instructions for full details of the set-up and operation of reflux cooling.

Important Note

Do not attempt to dismantle the Reflux Head – THIS WILL INVALIDATE

YOUR WARRANTY. Dismantling the Reflux Head may compromise the

silicone seal between the surfaces and cause a water leak during operation.

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

8.9. Connect Gas/Vacuum supply

The central gas inlet and radial distribution system combined with gas tight Easy-On PTFE

Caps allows reactions to be performed under an inert (nitrogen/argon) atmosphere.

For use under an inert atmosphere attach tubing to the central quick-release coupling and

connect via a 3-way tap or stopcock to a vacuum source and inert gas supply (recommended

maximum pressure 1psi).

Then, by alternately evacuating the system and filling it with a suitable inert gas (repeating

2 to 3 times) will achieve an inert atmosphere within the tubes.

The tubes can be isolated or removed during synthesis by simply closing the valve on the

Easy-On PTFE Cap and removing the tube.

Important Note

The Reaction Tubes can be isolated or removed during synthesis by simply

closing the valve on the Easy-On PTFE Cap ensuring the other reactions

remain under controlled inert conditions.

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important Note

If all gas connector positions are not in use, unused positions can be blocked

off with a Silicone Septa to ensure a satisfactory supply of gas to all reaction

tubes.

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Warning

When applying gas to the reaction station gas inlet system do not exceed 1

(one) psi as the Reaction Tube and Easy-On PTFE Caps are not rated for

pressure, (they are however suitable for applying a vacuum).

!