Smart Wi-Fi Module Series

SC20-WL Hardware Design

SC20-WL_Hardware_Design

79 / 81

8.2. Manufacturing and Soldering

Push the squeegee blade to apply the solder paste on the surface of stencil, making the paste fill the

stencil apertures and then letting it penetrate to the PCB. Downward squeegee pressure should be

adjusted properly to ensure that the stencil is wiped clean without damaging the stencil. To ensure the

module soldering quality, the recommended stencil thickness is 0.18mm~0.20 mm. As for LGA pads, less

soldering paste volume is recommended to avoid short circuits. For more details, please refer to

document [2]

.

It is suggested that the peak reflow temperature ranges from 240 to 245°C (for SnAg3.0Cu0.5 alloy). The

absolute maximum reflow temperature is 245°C. To avoid damage to the module caused by repeated

heating, remounting the module after finishing the reflow soldering of the first side of PCB is highly

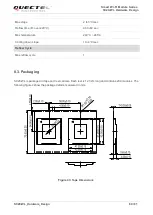

recommended. The recommended reflow soldering thermal profile is illustrated as follows.

Temp. (°C)

Reflow Zone

Soak Zone

245

200

220

240

C

D

B

A

150

100

Max slope: 1~3°C/

sec

Cooling

down slope:

1~4°C/sec

Max slope:

2~3°C/sec

Figure 42: Recommended Reflow Soldering Thermal Profile

Table 36: Recommended Thermal Profile Parameters

Factor

Recommendation

Soak Zone

Max slope

1 to 3°C/sec

Soak time (between A and B: 150°C and 200°C)

60 to 120 sec

Reflow Zone