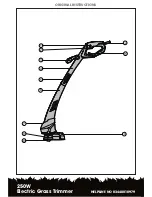

ORIGINAL INSTRUCTIONS

250W

Electric Grass Trimmer

HELPLINE NO 03448010979

other material and the line will become

jammed as a result. To clear the jam, follow

the steps listed below.

1) Unplug the trimmer.

2) Press the release tabs (c) on the spool

head, as shown in Fig P and remove the

spool head by pulling it straight off.

3) Remove the spool of nylon line out of the

spool head and clear any broken line or

cutting debris from the spool area. (If you

plan to replace the spool, this is the place

to do so, otherwise, move on.) (See Fig Q)

5

a

b

4

6

13

1

2

20

o

x

line

wrap

ring

c

eyelet

push

pull

A

B

C1

C2

D

E

F

G

H

I

J

K1

K2

L

M

N

O

P

Q

R

S

T

Q

4) Unwrap about one foot (30cm) of line

to ensure that it’s undamaged. If it is OK

rewind it and insert the line end through

the eyelet in the spool head as show in Fig

R, Insert the other line through the other

eyelet. Ensure the springs are in place

under the spool. Pull the line through the

hole to maintain tension while placing the

spool down into the spool head as show in

Fig R.

5) Press the spool down GENTLY until you feel

it drop into place. Take care to keep the

lines from becoming trapped under the

spool.

6) Snap the spool head cover back on and

at the same time pull lines and be sure

that they are released from spool rail

notches. If not, the function of bumping-

feed can not operate. Hold the tool in the

trimming position and turn the tool on. In

few sends or less, you’ll hear the nylon line

being cut to proper length. If not, bump

the feed head gently on the ground to

initiate a fresh length of line.

5

a

b

4

6

13

1

2

20

o

x

line

wrap

ring

c

eyelet

push

pull

A

B

C1

C2

D

E

F

G

H

I

J

K1

K2

L

M

N

O

P

Q

R

S

T

Q

4. SPOOL OR LINE REPLACEMENT

(Use 1.4mm diameter round line only)

1) Reform steps 3.1 and 3.2 above.

2) Remove the spool from the spool head,

remove the line wrap ring from the spool

and discard all line on the spool.(see fig

.R)

3)

WARNING!

Use only 1.4mm cutting

line. Other sizes of line will not feed

properly and will result in improper cutting

head function or can cause serious injury.

Take approximately 5m of line into the spool

holes and wind line in the direction of the

arrows on the top of the spool.

Care should be taken to ensure that the line

is neatly coiled on the spool. Failure to do so

will impair the efficiency of the automatic line

feed. (See Fig S)

Then fit the line wrap ring onto the spool and

snap the spool onto the spool head.

Note: Snugly and evenly wind the bulk line

onto the spool in the direction of the arrow