Page 22

10/08

Quadra-Fire • Columbia Bay • 250-5195 Rev. K

6

Gas Information

A. Fuel Conversions

Before making gas connections ensure that the appliance

being installed is compatible with the available gas type.

Any natural or propane gas conversions necessary to meet

the appliance and locality needs must be made by a quali-

fi ed technician using Hearth & Home Technologies specifi ed

and approved parts.

1. Converting to LP Gas

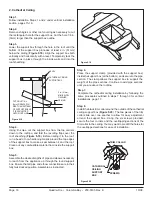

Figure 6.1

Loosen the shutter adjustment nut (located under-

neath the appliance) with a 7/16 in. wrench.

It is helpful to remove the nut completely. Slide the shutter to

the right (closed position).

Figure 6.2

Lift the burner from the left side and slide left until

free from the orifi ce receiver. Remove from the fi rebox and

handle with care.

Figure 6.3

With a 5/8 in. wrench remove orifi ce retaining nut.

Replace with appropriate orifi ce.

KIT CONTENTS: Replacement ori

fi

ce; replacement

pilot injector; valve regulator; conversion label.

TOOLS REQUIRED:

Power drill (a 90° handle is helpful); #2

Phillips bit; 5/32 in. Allen wrench; 5/8 in. open-end wrench.

If the shutter is removed with the burner as indicated in

Figure 6.2

, it must be reinstalled over the orifi ce prior to the

reinstallation of the burner.

PROPANE

NATURAL GAS

.0635 (52 DMS)

.1065 (36 DMS)

NOTE: Gas conversions should only be performed

by a qualified service person, and/or where required

by state and local codes, licensed installer/service

technician. In the Commonwealth of Massachusetts,

installation must be performed by a licensed plumber

or gas fitter.

Disconnect power and turn off gas supply if installed.

Remove the front, glass, brick refractory and logs if installed.

(It is only necessary to remove the left brick panel for burner

removal. The metal brick refractory does not need to be

removed.)

Figure 6.4

Remove the pilot hood, and set aside. Using a 5/32

in. allen wrench, remove the pilot injector and replace with an

appropriate injector (35 LP, 62 NG).

Reinstall the burner, and reassemble the appliance.

Opens Left

Closes Right