H

SZCZEGÓŁ H

SKALA 2 : 5

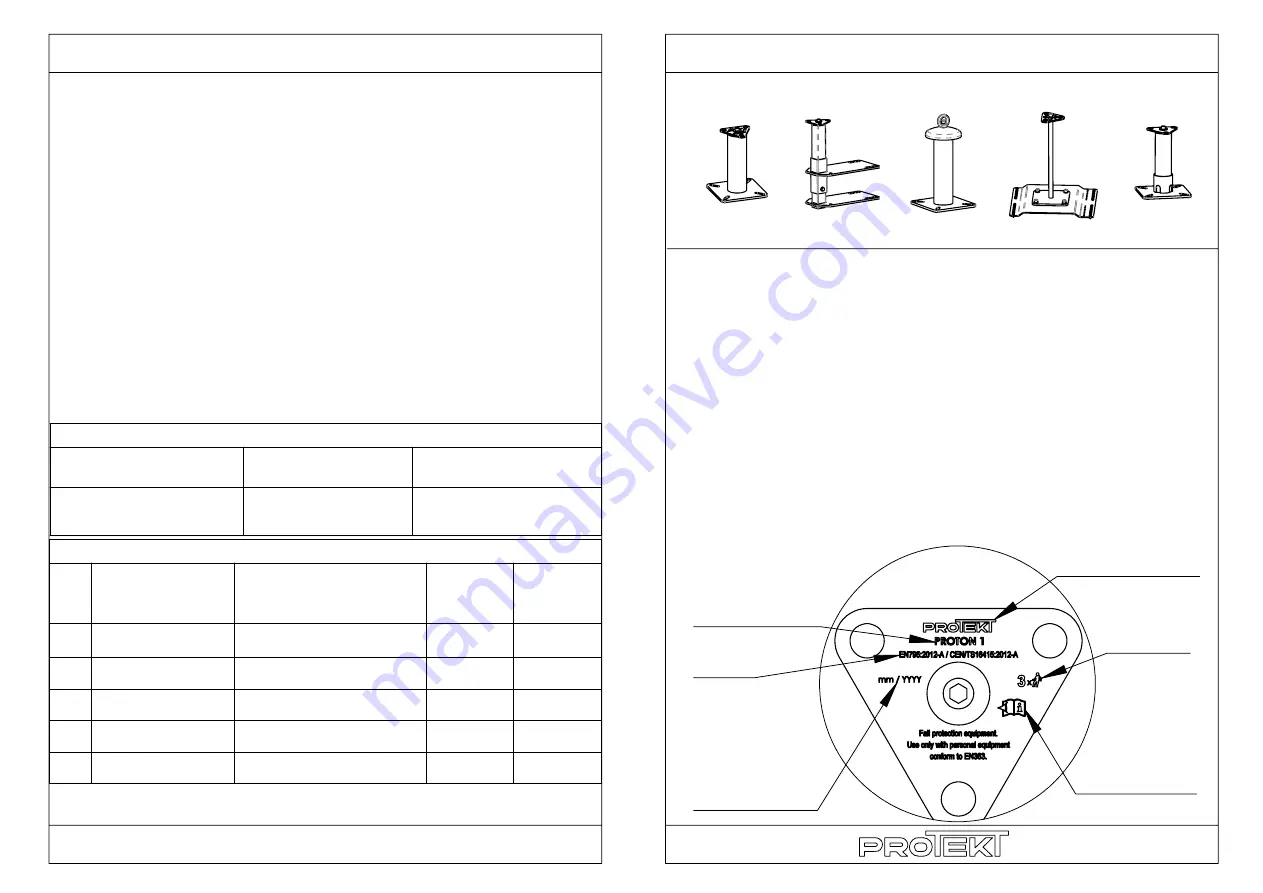

Batch number

=manufacturing date

(month / year)

Name of the device /

reference number

Standards

Number of

simultaneous

users

Read the Instruction

Manual before use.

Producer (or distributor)

marking

Name of the device:

Ref. number:

User name:

Manufacturing date:

Serial number:

Installation date:

Producer:

PROTEKT, 93-403 Łódź, ul.: Starorudzka 9, tel.: (+48 42) 680 20 93,

fax.: (+48 42) 680 20 93, e-mail: [email protected]

MARKING

PROTON 1 PROTON 2 PROTON 3 PROTON 4 PROTON 5

INSTRUCTION MANUAL

PRODUCT DESCRIPTION

The PROTON range of anchor devices conform to the EN 795:2012 standard

and the FprCEN/TS16415:2012. They are designed for connecting a personal

equipment against falls from a height to a fixed construction.

The PROTON1 (as well 2, 4, 5) consist of a pole of different height equipped

with rotating plate on it's top with three openings for conecting a personal

equipment. The PROTON3, on the pole top, is eqipped with flange and single

eye for connecting personal equipment. The PROTONs: 1; 2; 3; 5 are made of

hot deep galvanized steel. The PROTON4 is made of stainless steel.

Number of simultanous users: 3person for PROTON 1;2;4;5 and 1 person for

PROTON 3.

The PROTONS anchor devices may be installed by a people who have enough

knowledge and experience in this subject. The method of installation shoud

strictly follow the "PROTON installation manual" guidelines.

INSPECTIONS

Before each use a visual inspection should be carried out by the user to

1.

ensure that the anchor point is in good condition.

When the anchor point was engaged in fall arresting than it should be

2.

replaced with new one or submited under detailed inspection carried out

by qualified technician. The result of inspection and permission to further

usage shall be recorded in the Operational Sheet.

It is recomended that the device is periodically inspected every 12 month

3.

after installation. The periodic inspection must be carried out by a

qualified person. The result of inspection must be recorded in the

Operational Sheet.

During the inspections any mechanical, chemical or thermal defects

4.

(cracks, deformation or corrosion) should be taken into account.

When the anchor point was engaged in fall arresting than it should be

5.

replaced with new one or submited under detailed inspection carried out

by qualified technician. The result of inspection should be recorded in the

Operational Sheet.

In case of any doubt please contact with producer or its authorised

6.

representatives.

edition: 1-EN

OPERATIONAL SHEET

Technical examinations and repairing history

Date Reason for servicing /

repair

Device's condition after servicing

Next

examination

date

Name and

signature of

competent

person

ANCHOR DEVICE

PROTON

ANCHOR DEVICE

PROTON