2

3

4

5

Part 2 – Attaching the Mount Arms to the Display (continued)

0153-20191021

OPERATION AND ADJUSTMENT

A

Fig. 3

Fig. 4

NOTE:

This mount comes with a variety of screw lengths and

diameters to accommodate different display models. Not all of

the hardware in the kit will be used. If you cannot find the

appropriate screw size in the kit provided, consult with the

manufacturer of your display or a professional installer.

Part 2 – Attaching the Mount Arms to the Display

IMPORTANT!

Use extra care during this part of the installation

to avoid damaging your display.

Part 1B – Mounting to the Wall (Concrete) (continued)

While another person holds the

mount in place, mark four

locations for securing the mount

to the wall (see Fig. 3).

Set the mount aside and drill a

3/8” hole at each marked location.

Remove any excess dust from the

holes.

Insert a concrete anchor (C) into

each hole so that it is flush with

the concrete surface (see Fig. 4). A

hammer can be used to lightly tap

the anchors into place if

necessary.

Attach the mount to the wall with the arrow pointing up

using the lag bolts (A) and washers (B) provided (see Fig. 3).

Do not release the mount until all bolts are secure.

Ensure

that the mount remains level.

A

B

Attach the mount arms to the back of your display using

the screws identified in steps 1 and 2

(see Fig. 5):

If you are using the M4 and M5 screws you will need to

use the M5 Washers (F). If you are using M6 and M8

screws, you will need to use the M8 washers (K).

If you are using the longer screws, you may also need to

use spacers (L or M).

If the back of your display is flat and the mounting holes

are flush with the surface, use the shorter screws (D, E G

or H) from the hardware kit.

B

If the back of your display is curved or if additional space

is needed between the display and the mount, use the

longer screws.

2

Determine the correct diameter of screw to use by carefully

trying one of each size (M4, M5, M6 and M8) from the

hardware kit.

Do not force any of the screws – if you feel

resistance stop immediately and try a smaller diameter

screw.

1

Determine the correct length of screw to use by examining

the back of your display:

2

3

IMPORTANT!

The latches must be closed and locked at

all times to prevent the display from being accidentally

knocked from the mount.

IMPORTANT!

Never fully loosen or remove the level

correction nuts.

1

2

3

4

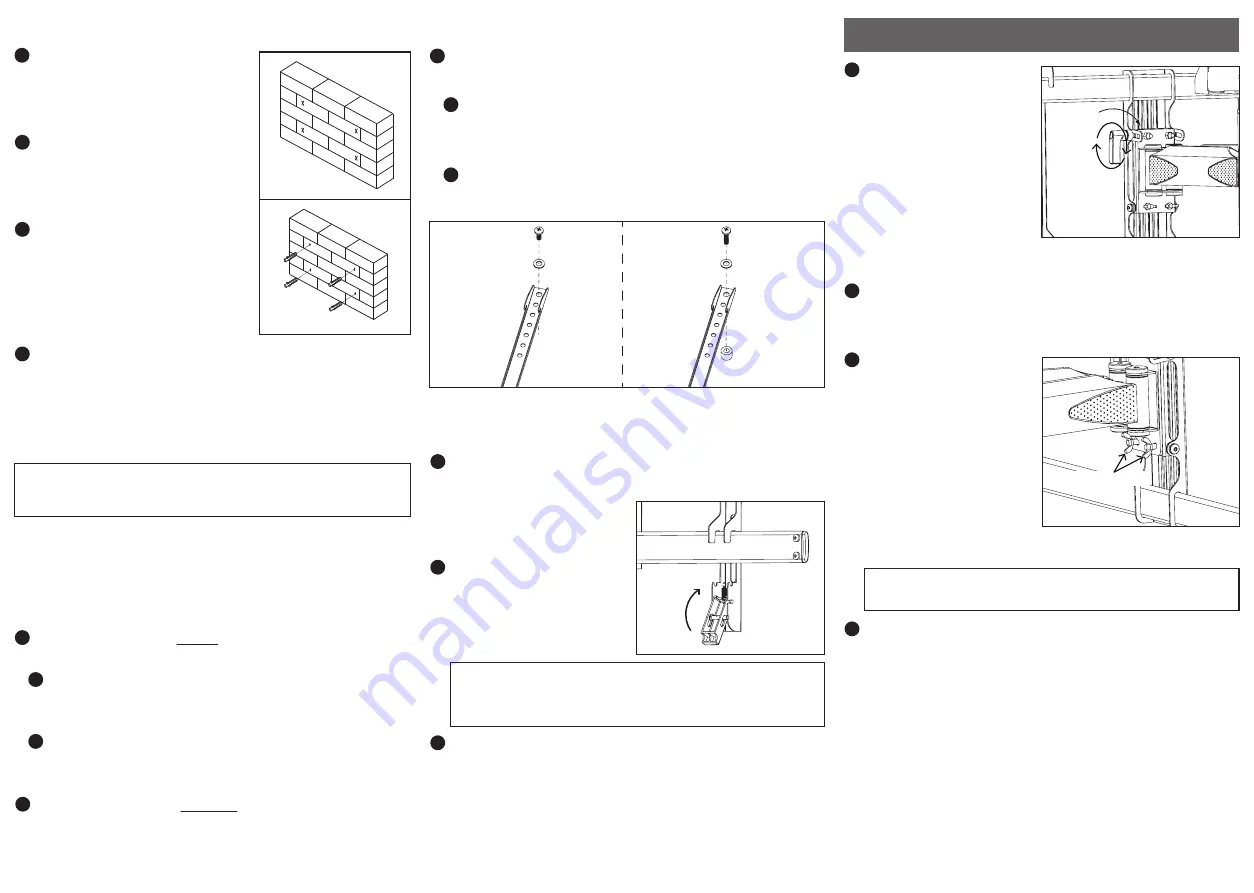

To change the tilt angle of

your display, have one

person hold the display

firmly in place while

another person loosens

the tilt knob (see Fig. 7).

Once loosened, move your

display to the desired

position, and then

re-tighten the knob.

Do

not release the display until the knob is fully tightened.

Swivel adjustments can be made by moving the display

to the desired position. Be careful that fingers or cables do

not get pinched when moving the mount.

Level correction

adjustments can be made

by rotating the display in

the needed direction. If it

is too difficult to turn the

display or if the display

does not stay in position,

adjust the tension of the

two wing nuts located

behind the faceplate.

Adjust the two nuts evenly (see Fig. 8).

1

With the help of another person, carefully lift your display

and place it on the mount.

Do not release the display

until the mount arms have

securely hooked onto the

mount.

Close the safety latch at the

bottom of each arm. Each

latch will automatically lock

when fully closed (see Fig. 6).

Periodically clean your mount with a soft, dry cloth. Inspect

all screws and hardware at regular intervals to ensure that

no connections have become loose over time. Re-tighten

as needed.

Cables can be routed through the channels located on the

bottom of the mount. Make sure none of the cables can be

pinched during operation of the mount.

Part 3 – Final Assembly

3

Fig. 5

For displays

with curved or

recessed backs.

For displays with

flat backs.

Fig. 8

Fig. 6

Fig. 7

Level correction nuts