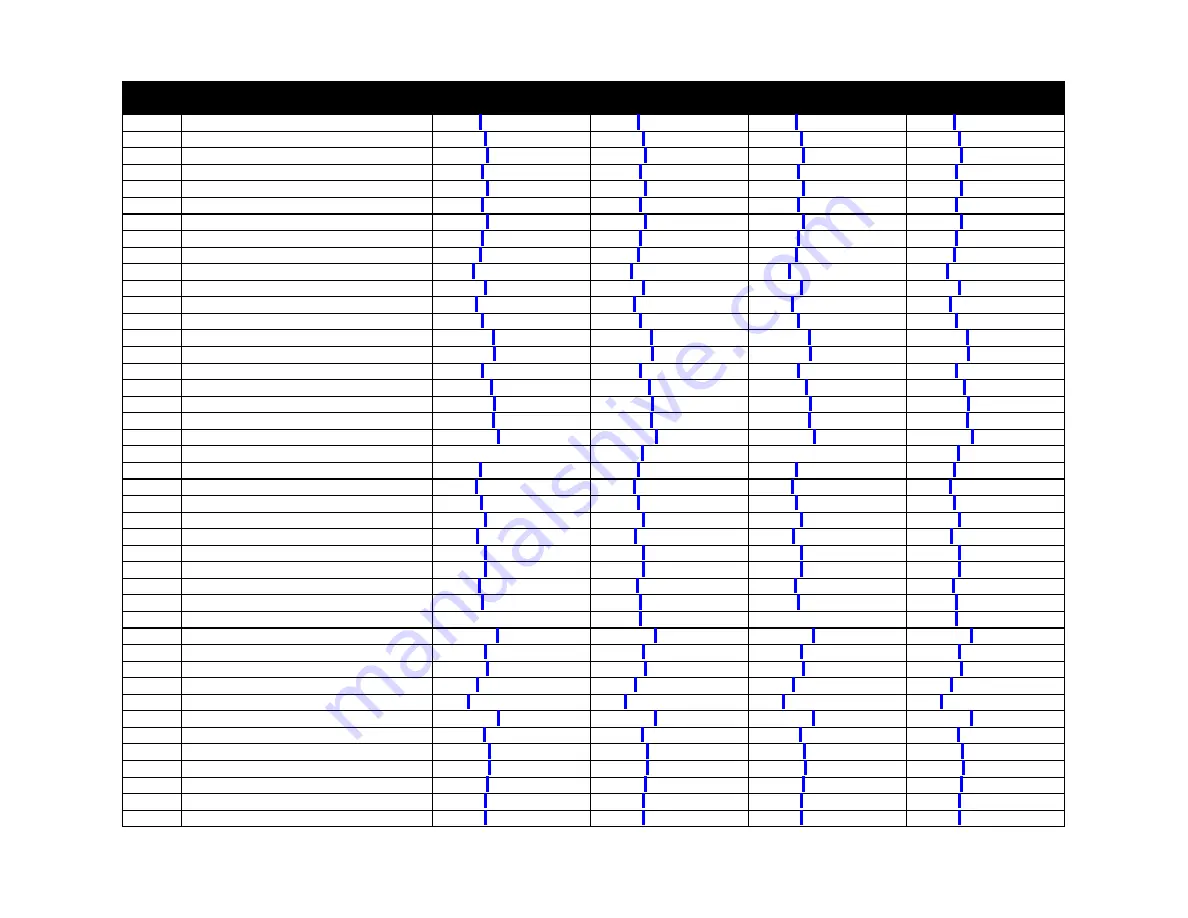

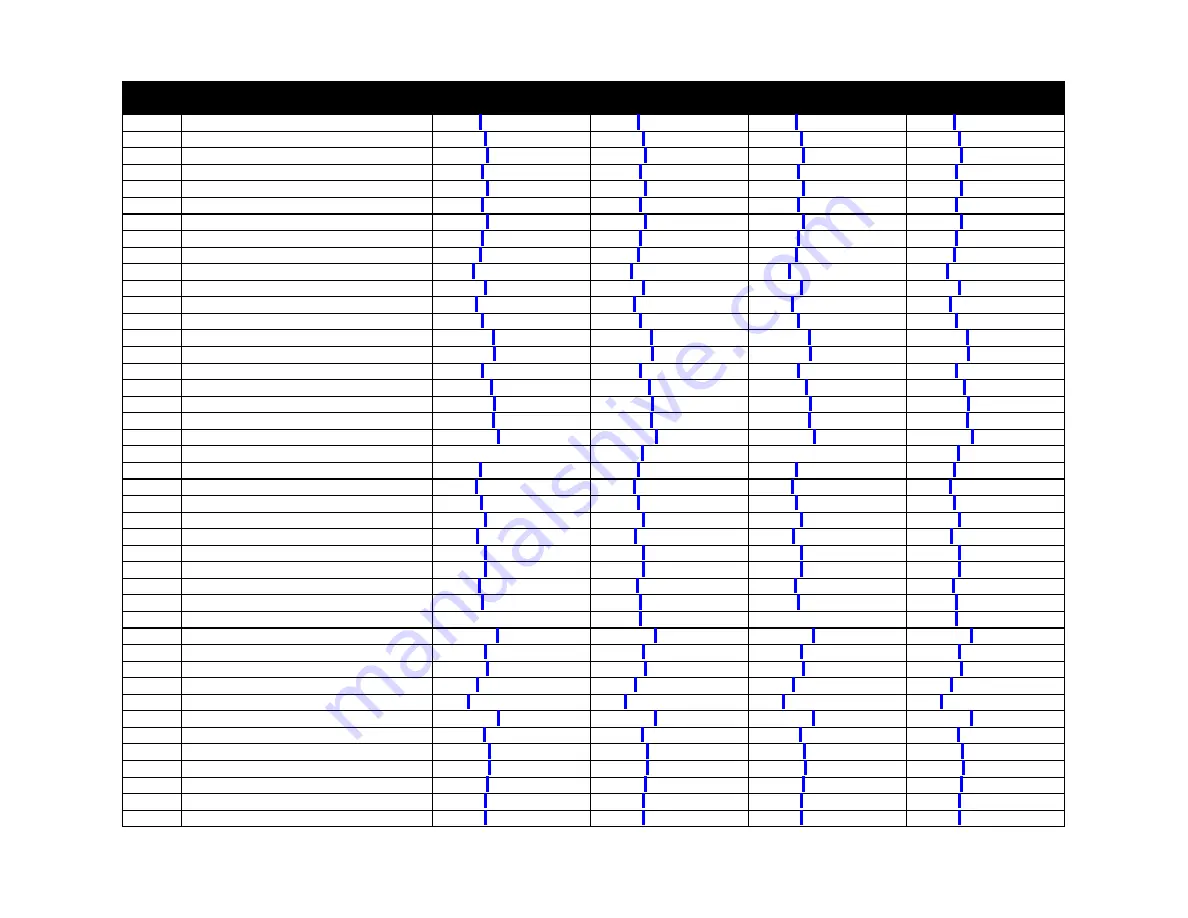

PROLUXE

PART

LIST

DP2000

DP2000B

DP2000LB

DP2000PB

DP2000PLB

240 ~ AC

240 ~ AC

240 ~ AC

240 ~ AC

REF. #

DESCRIPTION

44

SET SCREW, SENSOR

SST381638

SST381638

SST381638

SST381638

45

TERMINAL BLOCK

11098414

11098414

11098414

11098414

46

SCREW, TERMINAL BLOCK

SP83212

SP83212

SP83212

SP83212

47

SOLID STATE RELAY

MPR90217

MPR90217

MPR90217

MPR90217

48

SCREW, RELAY & TRANSFORMER

SP83214

SP83214

SP83214

SP83214

49

MICRO SWITCH

110969044

110969044

110969044

110969044

50

SCREW, MICRO SWITCH

SR44034

SR44034

SR44034

SR44034

51

WIRE HARNESS

110589050

110589050

110589050

110589050

52

SCREW, GEAR RACK

SSH381634

SSH381634

SSH381634

SSH381634

53

CONTROL PANEL OVERLAY

OPRODP1100

OPRODP1100

OPRODP1100

OPRODP1100

54

CONTROL FACIA

11086027

11086027

11086027

11086027

55

DIGITAL CONTROL

11096905220

11096905220

11096905220

11096905220

56

SPACER, NYLON

110969111

110969111

110969111

110969111

57

NUT, DIGITAL CONTROL

NH632

NH632

NH632

NH632

58

WASHER LOCK INT, DIGITAL CONTROL

WLIT6

WLIT6

WLIT6

WLIT6

59

POWER DIST CABLE

110589067

110589067

110589067

110589067

60

WASHER, GROUND

WSAE8

WSAE8

WSAE8

WSAE8

61

WASHER LOCK INTERNAL, GROUND

WLIT8

WLIT8

WLIT8

WLIT8

62

NUT, GROUND

NH832

NH832

NH832

NH832

63

TERMINAL BLOCK #6

6016

6016

6016

6016

64

NUT, HEX JAM

N/A

NHJ51618

N/A

NHJ51618

65

SCREW, HANDLE SWING

SSH142058

SSH142058

SSH142058

SSH142058

66

SCREW, COLLAR

SSH516181D

SSH516181D

SSH516181D

SSH516181D

67

SCREW, COLLAR

SST142034

SST142034

SST142034

SST142034

68

ORING, COLLAR

MPSS062

MPSS062

MPSS062

MPSS062

69

SCREW, COLLAR

SST5161834

SST5161834

SST5161834

SST5161834

70

COLLAR

11041323

11041323

11041323

11041323

71

BUSHING, BRASS (TENSION STRAP)

11018966

11018966

11018966

11018966

72

MICROSWITCH BRACKET

1101021213

1101021213

1101021213

1101021213

73

WOODRUFF KEY

KW931634

KW931634

KW931634

KW931634

74

RUBBER LEG

N/A

110288204

N/A

110288204

75

ZERK FITTING

B792

B792

B792

B792

76

ARM RETAINING PLATE

11056858

11056858

11056858

11056858

77

PIN, ROLL

PR18516

PR18516

PR18516

PR18516

78

SCREW, ARM RETAINING PLATE

SSH1213112

SSH1213112

SSH1213112

SSH1213112

80

BUSHING, INSTRUMENT HOUSING

212NN01420000

212NN01420000

212NN01420000

212NN01420000

81

ZERK, FITTING

B610

B610

B610

B610

82

SET SCREW, HANDLE SOCKET

SST14201

SST14201

SST14201

SST14201

83

WAVE WASHER

5806282

5806282

5806282

5806282

84

MARKER STRIP

MS6016

MS6016

MS6016

MS6016

85

WASHER, ARM RETAINING PLATE

WSAE12

WSAE12

WSAE12

WSAE12

87

FIBERGLASS INSULATION

MPSP251

MPSP251

MPSP251

MPSP251

88

FUSE HOLDER 1 AMP

MPPF708

MPPF708

MPPF708

MPPF708