8

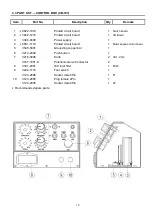

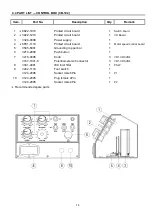

3.2 TROUBLESHOOTING GUIDE (CB-102)

SYMPTOMS

POSSIBLE CAUSES / REMEDIES

Weld timer function no

response.

A. Take VR Board JP2 connector off. Rotate the Start Delay knob and

measure JP2 Pin 1 & 2’s resistance. The value should vary from

0-10k

Ω. If there is no variation, check for any disconnection or

replace VR2.

B. Check for any loose cable connection between VR Board and Switch

Board.

Overload (Blinking Red LED)

Inspect the work and make sure it isn’t over-spec (weight /

eccentricity ...etc). Place the Work/Move switch (SW2) in “OFF” position

to reset the system.

Home sequence problem

A. Work / Move switch (SW2) malfunction, replace Switch Board.

B. If the green LED is flashing and there is no rotation, place the

Work/Move switch (SW2) in “Move” position and adjust the welding

speed knob (VR1) to desired speed. Restart the homing sequence.

C. Proximity switch too far

:

Adjust the proximity switch so it can sense

the homing block correctly.

D. Proximity switch malfunction: use a screwdriver to test trigger the

proximity switch. Replace when necessary.

Overlap delay function

inaccurate or no response

A. Take VR Board JP4 connector off. Rotate the OVERLAP knob and

measure JP4 Pin 1 & 2’s resistance. The value should vary from

0-10k

Ω. If there is no variation, check for any disconnection or

replace VR4.

B. Check for any loose cable connection between VR Board and

Switch Board.

Welding start delay function no

response

A. Take VR Board JP3 connector off. Rotate the START DELAY knob

and measure JP3 Pin 1 & 2’s resistance. The value should vary

from 0-10k

Ω. If there is no variation, check for any disconnection or

replace VR3.

B. Check for any loose cable connection between VR Board and

Switch Board

Summary of Contents for PT-103

Page 2: ......

Page 13: ...6 2 4 TIMING DIAGRAM CB 102...

Page 17: ...10 4 1 PART LIST MECHANISM PT 103...