PRO

WEL D

3 0 0 -0 8 0 5

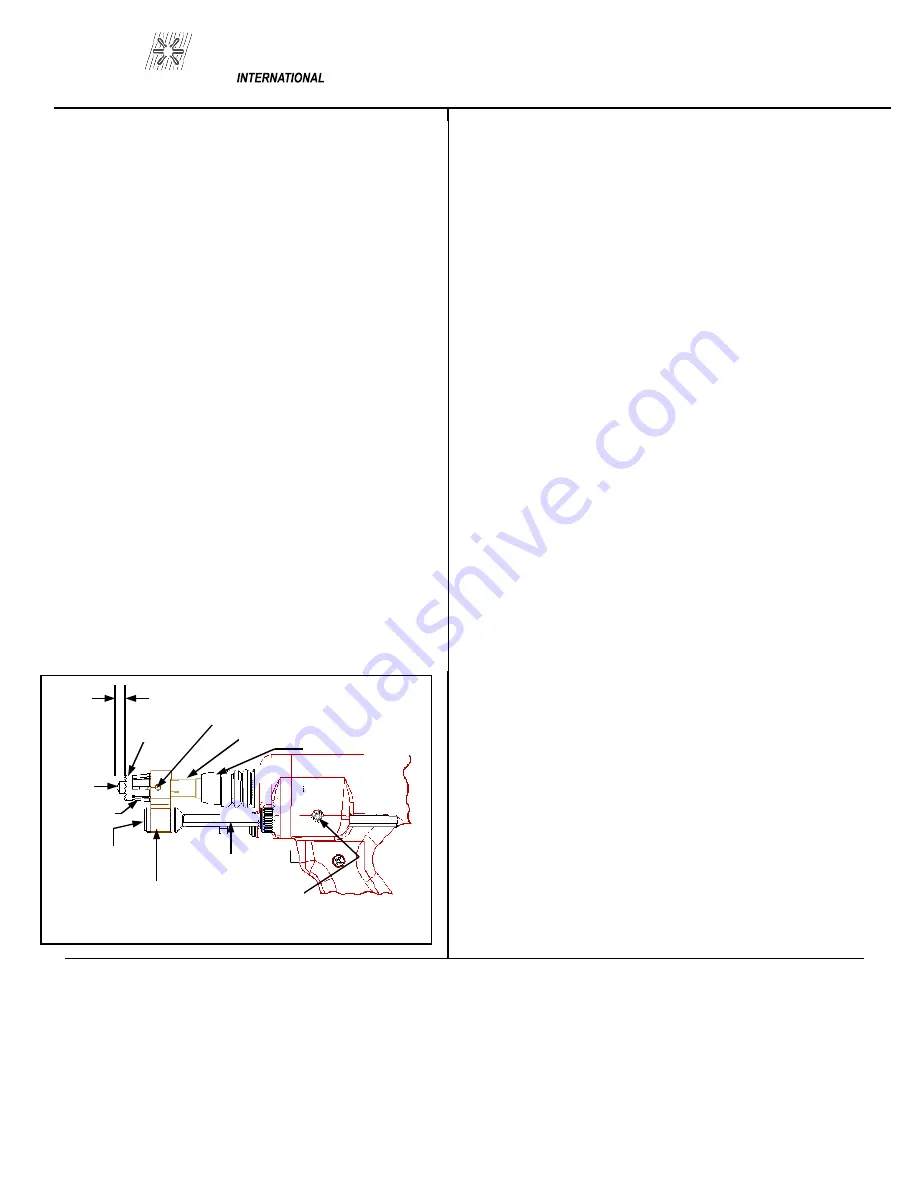

6.0 GUN SET-UP

The standard gun set-up is used for welding the ma-

jority of applications. It consists of the standard ad-

justable face plate, two legs, a foot, chuck adapter,

chuck, and spring for your specific stud size.

The following is a step by step explanation of the

correct way to set up the gun. (Refer to Figure 6-1)

1. A different, and correctly sized, chuck and ferrule

grip are needed for each different stud diameter and

style that will be welded. The appropriate chuck, or

stud holder, is inserted into the tapered chuck adapter

and tapped lightly to insure a tight fit. The ferrule

grip is inserted in the hole in the foot and secured

with the locking screws to hold it in place.

2. Studs must NOT bind or hang up on the foot, fer-

rule grip, or ferrule during the entire stud welding

process. To assure this, the foot/ferrule arrangement

must be centered in relation to the stud to be welded.

To assure centering, loosen the locking screws that

hold the foot to the legs. Place a stud in the chuck

and a ferrule in the grip. With the locking screw

loosened, the foot will move freely in all directions.

Adjust the foot so that the stud is centered in the fer-

rule and no contact occurs between the stud and the

ferrule during retraction or forward plunge of the stud.

Tighten the locking screws after centering the stud.

3. The “Plunge Length” is the amount of stud exposed

beyond the ferrule during initial set-up. Set the plunge

by loosening the leg adjusting screws and moving the

foot until the stud extends 1/8” to 3/16” past the end of

the ferrule. Tighten the leg adjusting screws after set-

ting the plunge and re-check centering to be sure the

stud is aligned properly in the ferrule.

4. The lift height, which determines the arc length,

has been pre-set at the factory and will automatically

lift and plunge the stud during the welding process.

“Lift” is the distance the gun will raise the stud above

the welding surface during the weld. This distance

governs the voltage and the arc. Improper lift will

cause unsatisfactory welds.

To measure the lift, turn the stud welding unit on and

set the timer to maximum time. (On certain units there

may be a Lift Check switch available, and in these

cases this switch can be used to check lift.) Trigger

the gun in the air or on a non-grounded or insulated

surface, to observe the lift cycle. Measuring the dis-

tance the stud or gun mechanism moves equals lift.

Usually this can be easily done by visual observation

or simple measurement against a static reference point

(i.e. the ferrule properly seated in the ferrule grip).

PAGE 3

Chuck Adaptor

Chuck

Locking Screws

Ferrule

Plunge Length

Stud

Ferrule Grip

(2) Foot

Screws

Foot

Leg

Leg Adj. Screw

Figure 6-1 GUN SET-UP

Summary of Contents for AG-805

Page 1: ...OPERATION MAINTENANCE MANUAL ...

Page 2: ......

Page 4: ...PRO WELD 300 0805 ...

Page 5: ...300 0805 PRO WELD ...

Page 6: ...PRO WELD 300 0805 ...

Page 7: ...300 0805 PRO WELD ...

Page 19: ...300 0805 PRO WELD ...