Hybrid Terminal Block Hardware Manual

1-2

1.1

About CANopen

1.1.1

Introduction

CANopen is an open fieldbus protocol for industrial control systems. It is particularly well suited to real-time

control, as it provides an effective, low-cost solution for integrated industrial applications.

1.1.2

The CANopen Protocol

The CANopen protocol was created as a subset of CAL (CAN Application Layer). It is widely utilized to

connect industrial components.

The CANopen standards are managed by CiA (CAN in Automation), promoting the adoption of various

applications. In Europe, CANopen is now the recognized standard for embedded systems in networks.

1.1.3

CANopen Profiles

The communication profile

The CANopen communication profile is specified into four message types by the CiA DS-301.

•

Real-time Data (PDO: Process Data Objects)

•

Configuration Data (SDO: Service Data Objects)

•

Special Function (Time Stamp, Sync Message, Emergency Message)

•

Network Administration Messages (Boot-up Message, NMT Message, Error Control)

For the details, please see the GP- Pro EX Reference Manual “Controlling External I/O”

The device profile

The most important types of devices used in factory automation are described in the “Device profiles”. They

also define device functionalities.

Examples of the standard devices described are:

•

digital and analog input/output modules (DSP-401),

•

motors (DSP-402),

•

measurement device (DSP-404),

•

other devices (DSP-4xx).

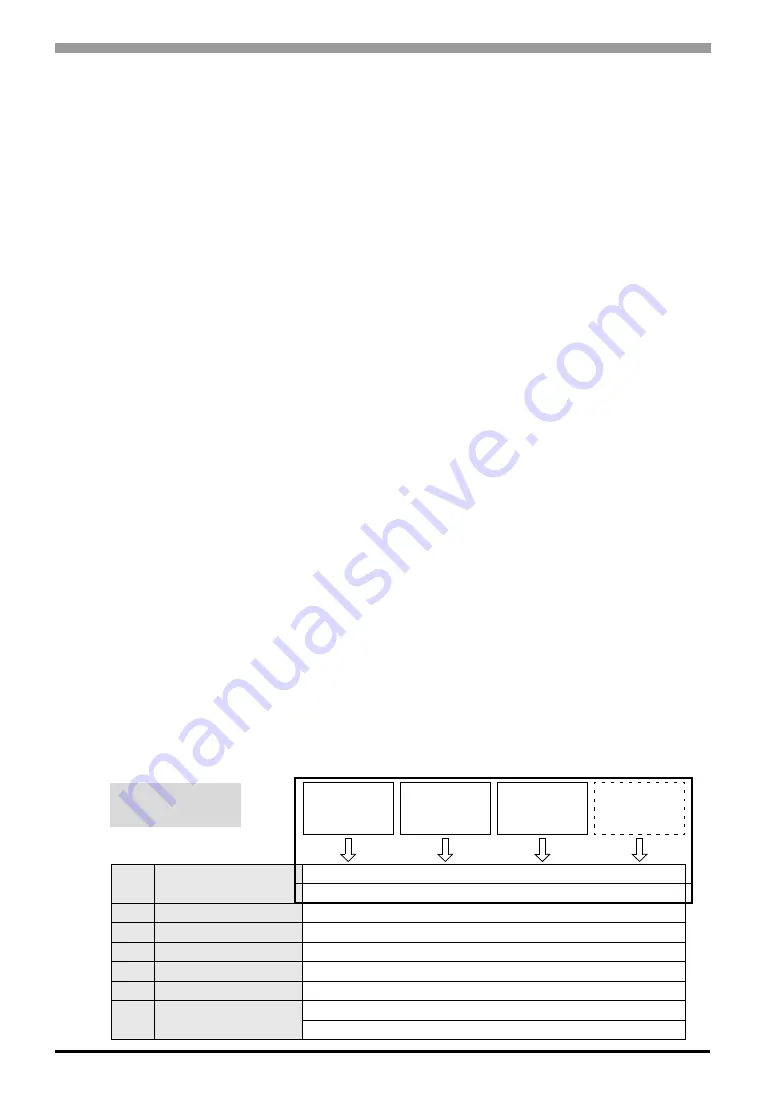

CANopen

is based on CAL

7

APPLICATION

CiA DS-301 = Communication profile

CAL = CAN Application Layer

6

PRESENTATION

EMPTY

5

SESSION

EMPTY

4

TRANSPORT

EMPTY

3

NETWORK

EMPTY

2

LINK = LLC + MAC

CAN 2.0 A and B + ISO11898

1

PHYSICAL

CAN 2.0 A and B = ISO11898-1 and 2

ISO 11898 + DS-102

Device Profile

CiA DSP-401

I/O modules

Device Profile

CiA DSP-402

Drives

Device Profile

CiA DSP-404

Measuring devices

Device Profile

CiA DSP-4xx