V160K

FILLING THE HYDRAULIC MOTOR

• The initial filling of the system must be carried out in such

a way that all of the air can escape from the high pressure

circuit and from the motor housings before the hydraulic

units are operated.

• Manually fill the motor housing at the most accessible

case drain port with

filtered oil

. Manually fill the high

pressure line(s) with

filtered oil

. Fill the oil reservoir to the

maximum level with

filtered oil

and fill the motor housing

to the maximum level via the most accessible case drain

port with

filtered oil

.

INITIAL START-UP

• The initial operation of the drive should permit it to rotate

freely

without load

.

• The drive should initially be

operated slowly and under

no load for a period of thirty minutes

.

• As the system purges itself of the air and as the hydraulic

oil warms up, steadily increase the load on the drive and

increase the speed of the motor.

ROUTINE MAINTENANCE

• Maintenance of the hydraulic system is limited to chang-

ing the hydraulic fluid and system filtration.

• In order to guarantee the proper function and efficiency

of the hydraulic motor, the purity of the hydraulic oil over

the entire operating period must comply to at least class

18/13 according to ISO 4406.

• With modern filtration technology, however, much better

values can be achieved which contributes significantly to

extending the life and durability of the hydraulic motor

and the complete system.

CHANGING THE FILTERS

• It is recommended that the filters be changed after the

initial start-up or at least 100 hours from the initial opera-

tion.

• NOTE: These recommendations are provided for guidance

to ensure long service life and proper operation of your

PRO-DIG

®

drive. However, depending on the operating

conditions of the drive, it may not be necessary to adhere

to these recommendations as long as the oil cleanliness

level and oil viscosity specifications are strictly adhered to

and monitored.

CHANGING THE HYDRAULIC FLUID

• Oil changes are carried out by first draining the reservoir,

cooler and motor housings. The high-pressure fluid must

be changed after 1000-2000 hours of operation, depend-

ant on the application.

• High working temperatures and frequent cooling-down

phases with low temperatures condense water and will

shorten the life of the hydraulic fluid.

• The oil remaining in the high-pressure circuit itself need

not be changed. Do not open up the high pressure lines

if possible. The instructions regarding initial filling must

be adhered to when changing the hydraulic fluid. In some

applications, a complete oil change may not be necessary.

the oil lost during each filter change must be replaced by

fresh filtered oil.

V160K HYDRAULIC MOTOR START-UP INSTRUCTIONS, CONT.

WWW.PRO-DIG-USA.COM

8.

Summary of Contents for V160K

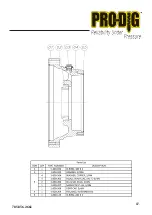

Page 15: ...785 856 2661 15 ...

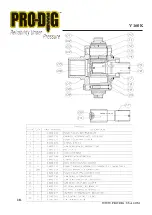

Page 16: ...V160K WWW PRO DIG USA COM 16 ...

Page 17: ...785 856 2661 17 ...

Page 18: ...V160K WWW PRO DIG USA COM 18 ...

Page 19: ...785 856 2661 19 ...

Page 20: ...V160K WWW PRO DIG USA COM 20 ...

Page 21: ...785 856 2661 21 ...

Page 22: ...V160K WWW PRO DIG USA COM 22 ...

Page 23: ...785 856 2661 23 ...

Page 24: ...V160K WWW PRO DIG USA COM 24 ...

Page 25: ...NOTES 785 856 2661 25 ...

Page 26: ...PROUD MEMBER OF 1604 ROSEPORT RD ELWOOD KS 66024 785 856 2661 WWW PRO DIG USA COM ...