07

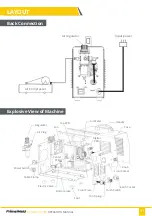

Cut50dp with 50 Amps cutting current.

15mm Max Cutting thickness on Steel.

Inverter with Industrial Rated, Lightweight and Portable.

PARAMETER

• Latest IGBT Inverter Technology

• Safe torch connection

• High quality cutting torch with quality cable

• Industrial application

• Tolerant to variable power supply

• Quality Air regulator with preset air pressure

• Suitable to cut all electrically conductive materials

• Light weight and compact

• Strong metal housing

Amperage

Amperage

Model

Power Supply / Phases (V-Ph)

Duty Cycle @ 78°F ( 25 C)

Input Current Range (A)

220V +/-15%

60%@ 50Amps

35-40

40-45

60%@ 40Amps

Rated Power (KVA)

5.90

4.40

Output Current Range (A)

20-50 Amps

20-40 Amps

Rated Output Voltage (V)

100

96

No-Load Voltage (Open CricuC(V)

260

260

Efficiency (%)

60

60

Insulation Class

F

F

Protection Class

IP21S

IP21S

Plasma Arc Starting

HF Touch

HF Touch

Air Flow Pressure Range (PSI)

40 - 65 psi

40 - 65 psi

Air Flow Rate (CFM)

5 L/min

5 L/min

Clean Cutting Thickness (mm)

12mm

12mm

Cutting Thickness Severance (mm)

16mm065psi

12mm065psi

Shipping Weight (kgs)

8.9kgs

8.9kgs

Cutting speed 10mm

200mm/min(065 psi 150mm/minG65 psi

Machine Dimenswns (inch)

13 7 x 5 6" x 9 2"

13 7 x 5 6" x 9 2"

110V +/-15%

Cut5ODP (110/220V)

220V

110V

PLASMA CUTTER

OPERATION MANUAL