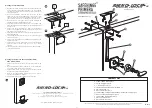

A) Installing Tubular Bolt

1) On the edge of the door (top or bottom accordingly) mark a

pencil line 80±100mm from the edge of the door

representing the centre line for the tubular bolt. (Diagram 1).

2) Carefully drill a 25mm diameter hole through the core of

the door 300mm deep. Take great care to ensure the drill

is kept straight in both planes throughout the drilling

process to prevent damaging the door.

3) Ensure all debris is removed and check the bolt sits

comfortably in the hole all the way to the back of the

fore-end without force.

4) Mark a pencil line around the face-plate and remove the

bolt (Diagram 2).

5) Using a chisel remove 3mm of timber inside the

guide-lines to enable the front of the bolt to sit flush with

the surface of the timber when face-plate is fitted

(Diagram 3).

6) Withdraw the bolt and set aside.

B) Fitting the Escutcheon Assembly

1) Mark 270mm backset distance. (Diagram 4).

Using a 22mm flat bit, drill the hole to receive the spindle

and key-drive housing. Re-fit the Tubular Mortise Bolt

and check to ensure the hole is perfectly aligned

centrally to the square follower. Offer the escutcheon

assembly up to the door and mark the position of the

protruding machine screws. Drill two appropriate holes

that will enable the plate to sit flat against the surface of

the door. (Diagram 4).

2) It is important to ensure the lock is fitted the correct way

round in the mortise. Please ensure that the coloured spot on

the side of the tube faces the side of the door that the

escutcheon assembly will be fastened to (Diagram 3).

3) Using the spindle formula in figure (5) cut the spindle to the

required length. Secure the spindle in the escutcheon

assembly using grub screw supplied. Ensure that the grub

screw is fully tightened using 1.5mm Allen Key (Diagram 6).

4) With the key indent at the 12.00 o’clock position and with the

bolt withdrawn, offer the escutcheon assembly on to the door

aligning the spindle in to the tubular bolt. Test the key to

ensure bolt works properly.

5) Using the 2mm drill, carefully drill four pilot holes for the plate

fixings (Diagram 4).

6) Fasten the Escutcheon Plate to the door using 4 x 5/8” No 6

screws. The plate must be sat firmly back to the surface of the

door to prevent any potential ligature risk.

7) Using the key, operate the lock again to ensure the bolt can

be thrown and withdrawn easily.

8) Using the bolt fore-end as a guide pilot drill two holes and

secure bolt and faceplate in position using 2 x 1”¼ No. 8

screws.

44

80±100

44

80±100

44

80±100

44

C) Installing Reinforcing Plates

1) Mark a vertical line on the surface of the door representing the centre

line of the bolt and mark 2 parallel lines 35mm on either side

(Diagram 7a).

2) If fitting at the head of the door mark a horizontal line on the surface

of the door 3mm below the rebate (if applicable) at the top of the door

(Diagram 7b). If fitting to the bottom of the door mark a horizontal line

on the surface of the door 3mm from the bottom edge.

3) With the reinforcing plate centred and outside edge aligned with the

horizontal line mark the 4 fixing points in preparation for drilling.

4) Using the 6mm drill bit drill through the door ensuring correct

horizontal and vertical alignment and taking measures to prevent the

possibility of spelching on the opposite side.

5) Fasten the reinforcing plates on to the door using the back to back

fixings as illustrated (Diagram 8). Ensure that the screw heads are

positioned on the safest side of the door preferably outside the

patient environment or on the observed side of the door. It may be

necessary to drive the knurled sleeve fixings home using a nylon

faced hammer/mallet to ensure they are seated correctly in the plate.

6) Complete the installation by fitting the remaining four M4 machine

screws and ensure both plates are fitted firmly back to the door.

a) Heavy Duty Drill (Mains)

b) 25mm Auger Bit (350mm-400mm)

c) 6mm Drill Bit

d) 2.0mm Drill Bit

e) 22mm Flat Bit

f) 13mm Flat Bit

g) Chisel 1”

h) Chisel ½”

i) Hex Socket Screwdriver

j) T15 Pin Torx Bit

k) T20 Pin Torx Bit

l) Hammer

m) Tape Measure

n) Pencil

o) Nylon Faced Hammer/Mallet

p) 1.5mm Allen Key

q) Life-Line Key - Pn. PR7320-LLBK (not included)

When fitting the easy-clean socket in a concrete

floor:

r) 7mm Masonary Bit

s) Narrow Cold Chisel

Door Thickness

2 + 7mm = Spindle Lgth

Example where door is 44mm

44mm

2 + 7mm = Spindle Lgth of 29mm

Installation Procedure

(Assumes timber doors without obstacles eg. viewing panels that would affect positioning)

Spindle Formula

22mm

(a)

(b)

80±100

44

270 Backset

1

4

5

6

7

8

2

3

Rhino Bolts should be fitted in pairs, use the same procedure to install the bolt at the foot of the door.

= Mark with pencil

= Drill Pilot Hole

Tools Required