11

ENGLISH

Keep in mind to disconnect the tool before cleaning or

servicing.

Every component in the tool is an important part of the

insulating system and should only be serviced in a

Authorized Service Center.

When sending the tool to maintenance, ALWAYS ask for

original spare parts.

When cleaning the plastic parts of the tool, refrain from

using solvents. Most plastic materials are susceptible to

damage when commercial type solvents are applied.

Use a clean cloth or pressurized air to clean dirt, coal or

dust.

A DVERTEN

NEVER put the tool in contact with

brake oil, petroleum-based products, penetrating oils, etc.

Those products contain chemical substances that damage

or destroy plastic.

When using pressurized air to clean

particles ALWAYS wear safety glasses with side protection

or a face mask. If it expels too much dust, also wear an

anti-dust mask.

It is not advisable to use this tool for extensive work in

fiberglass materials, gypsum wallboard, plaster or stucco.

The particles are highly abrasive for any power tool

components. If using the tool with those materials, it is

very important to frequently blow pressurized air to

increase the useful life of the tool.

Maintenance

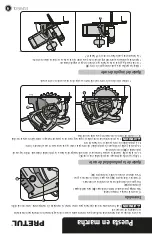

• Carbon brushes shall be checked periodically and

replaced always in a Authorized

Service Center when worn.

• After being replaced ask to inspect if the new carbon

brushes can move freely in the carbon brush housing. Ask

to turn ON tie tool 5 minutes to make even the contact

between the carbon brushes and the commuter.

• Use only original spare carbon

brushes specifically designed with the hardness and

resistance adequate for each type of motor. Carbon

brushes that are out of specification

may damage the motor.

• When replacing carbon brushes, always replace both.

Carbon Brush Replacement

WARNING

WARNING

Summary of Contents for 27098

Page 12: ...Notes 12 ENGLISH ...

Page 17: ...Notas 12 ESPAÑOL ...