16

Copyright © 2020 Quality Machine Tools, LLC

PM-1440GT v9 2020-10

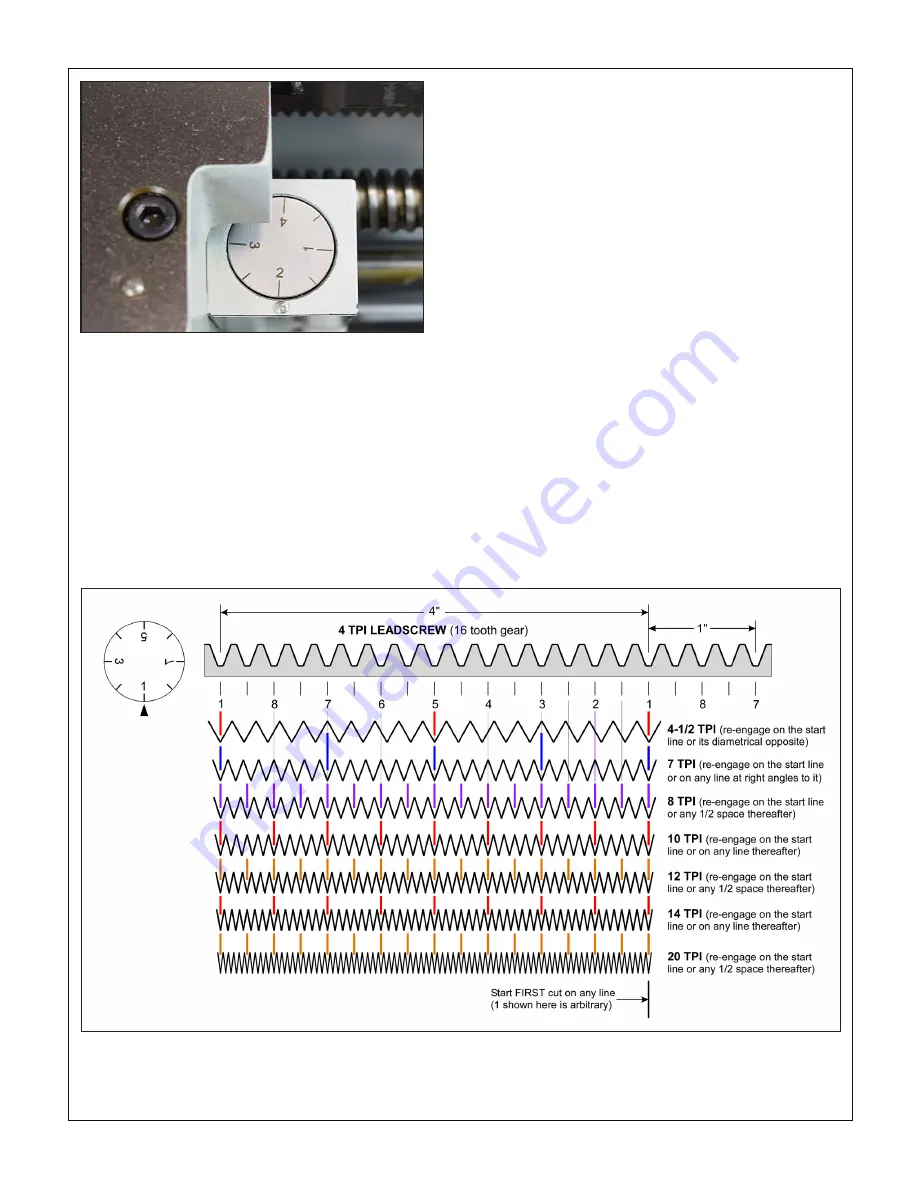

USING THE THREADING DIAL

Referring to Figure 3-23, the general rules are:

1. Divide the TPI value by 2: If this gives an

EVEN whole

number

, example 12/2 = 6, re-engage at

any line

on the

dial, also

mid-way

between the lines. (This equates to the

16 choices on the dial plate, Figure 3-24.)

2. If the ÷ 2 result is an

ODD whole number

, examples 10/2

= 5, 14/2 = 7, re-engage at

any line

on the dial, but

NOT

mid-way between the lines.

3. If the TPI value is a whole number not divisible by 2, ex-

ample 7, re-engage on the start line, or any line at right

angles to it.

4. If the TPI value is fractional, but becomes a whole number

when multiplied by 2, example 4-1/2, re-engage only on

the start line, or its diametrical opposite.

If in doubt, re-engage on the start line!

dial comes into alignment with the datum mark. If not, the sec-

ond and subsequent passes will be out of sync. In some cas-

es, Figure 3-23, there is a choice of lines for re-engagement,

but in every case the process calls for careful timing. [

NOTE:

Disengagement and re-engagement of the split-nut is not ap-

plicable to metric threads].

Typical depths of cut per pass vary from an initial 0.005” or so,

to as little as 0.001”, even less. A finishing pass or two with

increments of only 0.0005” — or none at all, to deal with the

Figure 3-22

Threading dial

Figure 3-23

Threading dial visualization for selected U.S. threads

Minimize wear by swinging the dial indicator assembly away from

the leadscrew when not in use

spring-back effect, can make all the difference between a too-

tight thread and one that runs perfectly.

Assuming that the compound is set over at between 29 and

30 degrees, the total depth of cut is approximately 0.69 times

the thread pitch, P (this equates to a straight-in thread depth of

0.6 times P). There may be a need for a few thousandths more

in-feed than 0.69P, almost certainly not less.