PD6700 Field-Mount Loop-Powered Process Meter

Instruction Manual

12

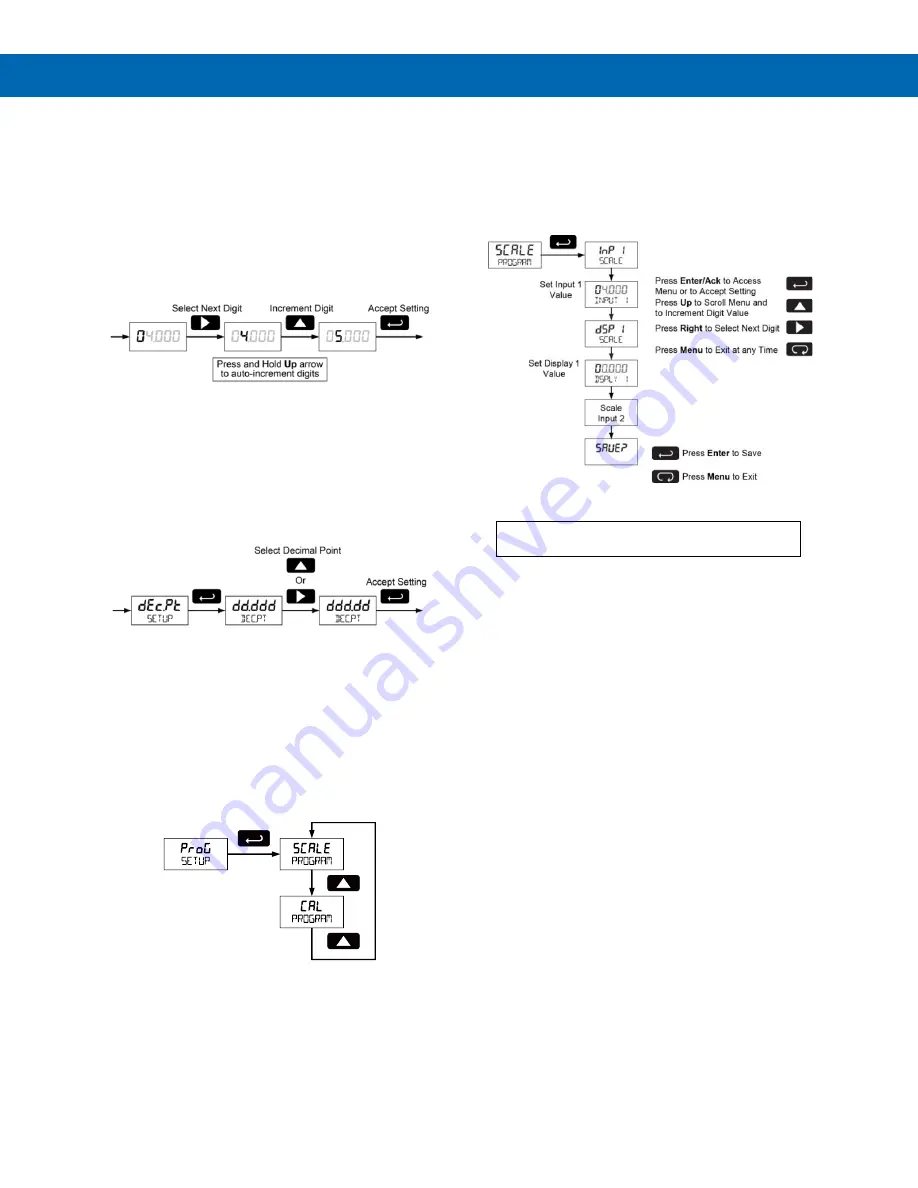

Setting Numeric Values

The numeric values are set using the

Right

and

Up

arrow buttons. Press

Right

arrow to select next digit

and

Up

arrow to increment digit.

The digit being changed blinks.

Press the

Enter

button, at any time, to accept a

setting or

MENU

button to exit without saving

changes.

The decimal point is set using the

Right

or

Up

arrow

button in the

Setup-decimal point

menu.

Setting the Decimal Point (

Dec.Pt

)

Decimal point may be set with up to four decimal

places or with no decimal point.

Pressing the

Right

arrow moves the decimal point

one place to the right until no decimal point is

displayed. Pressing the

Up

arrow moves the decimal

point one place to the left.

Programming the Meter (

Prog

)

The meter may either be scaled (

SCALe

) without

applying an input or calibrated (

Cal

) by applying an

input. The meter comes factory calibrated to NIST

standards, so for initial setup, it is recommended to

use the (

SCALe

) function. The Program menu contains

the Scale (

SCALe

) and the Calibrate (

Cal

) menus.

Process inputs may be scaled or calibrated to any

display within the range of the meter.

Note: The Scale and Calibrate functions are exclusive

of each other. The meter uses the last function

programmed. Only one of these methods can be

employed at a time. The Scale and Calibrate

functions can use up to 32 points (default is 2). The

number of points should be set in the Advanced

Features menu under the Multi-Point Linearization

menu selection prior to scaling and calibration

of the meter, see Advanced Features Menu, page 15.

Scaling the Meter (

SCale

)

The 4-20 mA input can be scaled to display the

process in engineering units.

A signal source is not needed to scale the meter;

simply program the inputs and corresponding display

values.

For instructions on how to program numeric

values see