22

User Manual

Zenex-ultra

DESCRIPTIONS

The back panel connections are described as under:

INPUT

(Terminals : 1, 2, 3)

The Indicator accepts Thermocouples (J, K, T, R, S, B, N), 3-wire RTD Pt100 and DC Linear Current/Voltage (mA/mV/V) as

input.

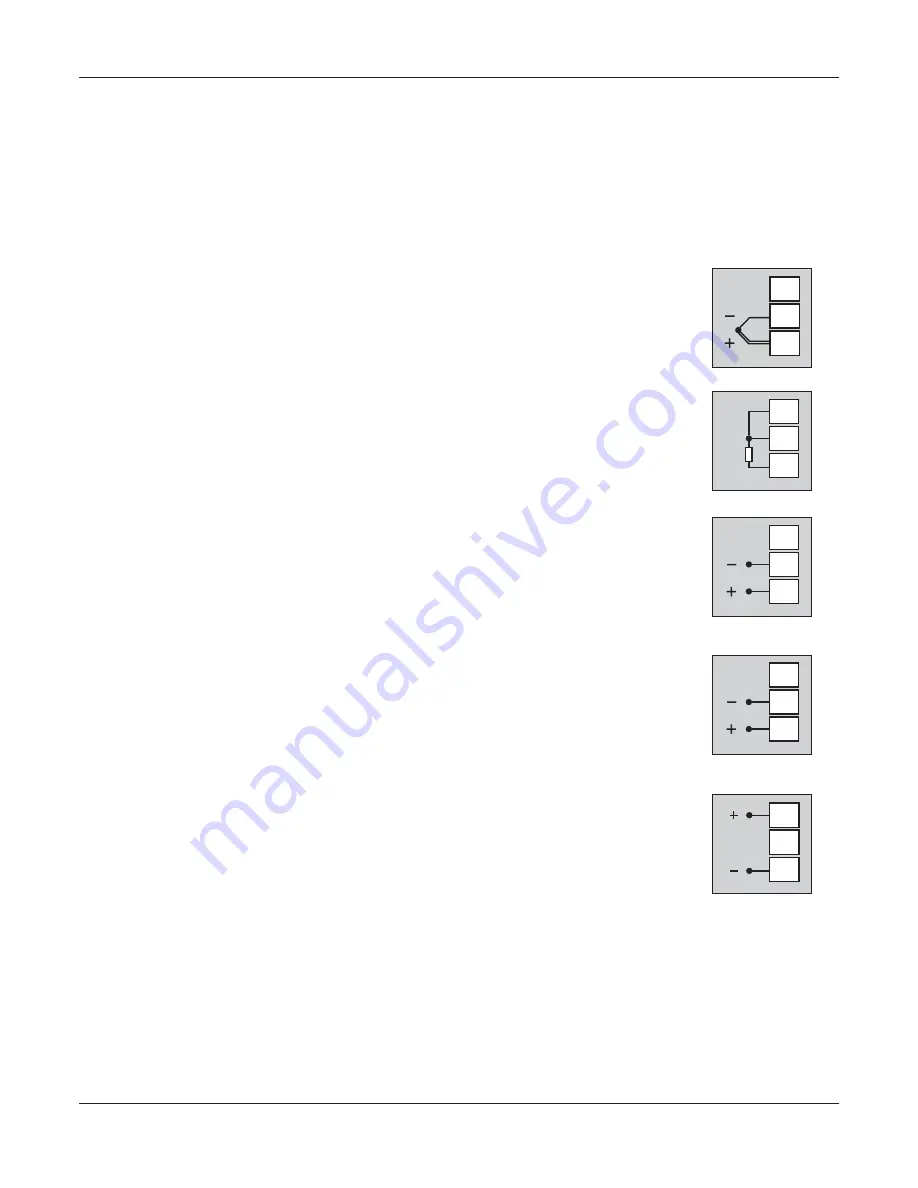

Thermocouple

Connect Thermocouple Positive (+) to terminal 1 and Negative (-) to terminal 2 as shown in Figure

12.2 (a). Use the correct type of Thermocouple extension lead wires or compensating cable for the

entire distance ensuring the correct polarity throughout. Avoid joints in the cable.

3

2

1

Figure 12.2 (a)

RTD Pt100, 3-wire

Connect single leaded end of RTD bulb to terminal 1 and the double leaded ends to terminal 2 and 3

(interchangeable) as shown in Figure 12.2 (b).

Use copper conductor leads of very low resistance

ensuring that all 3 leads are of the same gauge and length. Avoid joints in the cable.

3

2

1

Figure 12.2 (b)

DC Linear Voltage (mV / V)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mV / V

source. Connect common (-) to terminal 2 and the signal (+) to terminal 1, as shown in Figure 12.2

(c).

Figure 12.2 (c)

3

2

1

DC Linear Current (mA)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mA source.

Connect common (-) to terminal 2 and the signal (+) to terminal 1, as shown in Figure 12.2 (d).

Make sure that the Jumper Pins for Input selection are shorted using the Shorting-Link (Refer

S

ection 10 Hardware Assembly and Configurations, Input-Jumper Settings).

Figure 12.2 (d)

3

2

1

OUTPUT-1

(Terminals : 4, 6)

DC Linear Current / Voltage Output

The DC Linear (0/4-20 mA) Current or (0-5/10V) Voltage output is also available at Terminal 6 (+)

and Terminal 4 (-) for Retransmission (Recorder) output. Refer Figure 12.3.

Figure 12.3

6

5

4

OUTPUT- 2

(Terminals : 7, 8, 9)

OUTPUT- 3

(Terminals : 16, 17, 18)

The Output-2 and Output-3 are available through plug-in modules that can be configured as Relay or SSR through appropriate

Jumper Settings. The connection descriptions are shown in figures 12.4(a) and 12.4(b).