3.2 Transmitter Memorizing and Erasing Process

3.3 System Learning, Reset Process, and LED Display

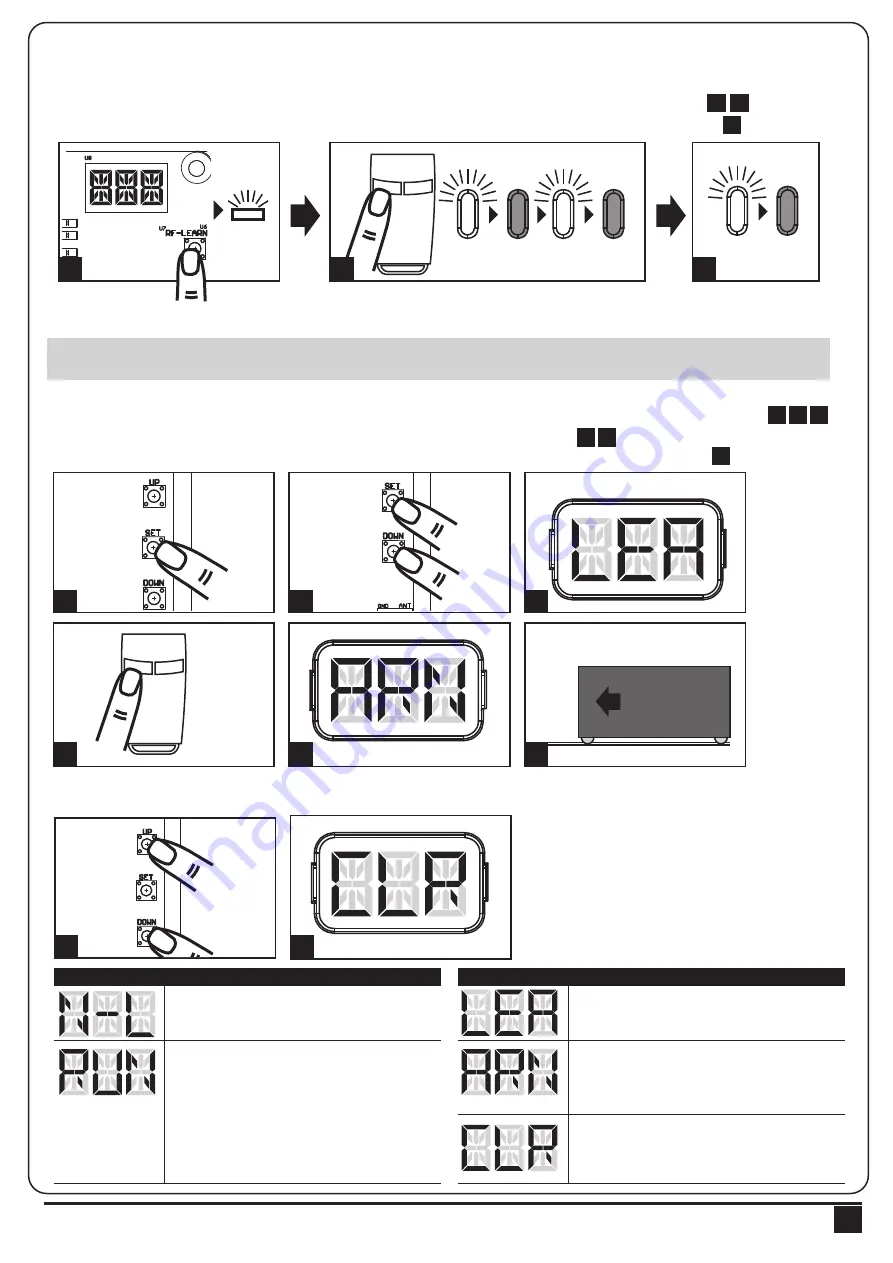

(1) To Complete the System Learning:

Step1: Press “SET”; then press “SET” + “DOWN” for 3 seconds, and the LED display shows “LEA”

Step2: Press left button (A) on time, the LED display should show “ARN”

Step3: The gate goes to Auto-learning, please wait for the learning process to be completed

(2) To Reset Factory Setting:

Press UP and DOWN for 3 seconds, and the LED display shows “CLR”

(1) Transmitter Memorizing: Press “RF Learn” button for 2 seconds, and the LED3 is on; then press the transmitter

left button (A); the LED3 will blink twice and then be off. The transmitter learning is completed.

(2) Erasing Memory: Press "RF Learn" button for 5~6 seconds as LED3 is on, then wait for LED3 off.

LED 3

2 Sec

LED 3

blink twice

LED 3 OFF

1

3

12

13

14

LED1

LED2

LED3

ON

OFF

Press

1~3 Sec

Press

3 Sec

Push

1

2

3

4

5

6

14

LED1

LED2

LED3

ON

OFF

2

3

4

5

6

7

8

9

10

11

12

13

14

LED1

LED2

LED3

ON

OFF

Push

3 seconds

1

2

LED Display

Programmable Functions

LED Display

Programmable Functions

“N-L”: The PL500 system learning is not done.

“LEA”: Enter learning mode and then wait for

learning instructions.

“CLR”: Reset Factory Setting.

“ARN”: The system learning is in progress.

The Auto-learning process of gate moving:

“Gate open to the end- stop close to the

end- stop.”

“RUN”: The PL500 system is in normal

operation To program, press SET button for 3

seconds, when the LED display change from

RUN to F1, press UP or DOWN to change

function settings (F1 to FA). Then press SET

to enter the sub function within each group,

press UP or Down to select sub functions

and press SET for confirmation.

! CAUTION: Before proceeding to system learning, the transmitter memorizing process has to be completed.

INSTRUCTIONS PL500 SLIDING GATE OPENER USER MANUAL

7

1

1 2

4 5

6

3

2

3

14

LED1

LED2

LED3

ON

OFF

A

B

A

B

2