4

The Model 20FS staples fl ooring from 5/16” to 1/2” through

the use of a FLEX foot that can be adjusted to fi t different

fl ooring profi les.

To use the Model 20FS, simply snug up the fl ooring, pull

the safety trigger and let the Stapler drive and set the

staple at the correct 45 degree angle.

The unique body design allows for different grip angles and

has an adjustable exhaust port to redirect stapler exhaust.

For a superior pneumatic stapler, look to the company

that has been the industry’s quality leader, Powernail®

Company, Inc.

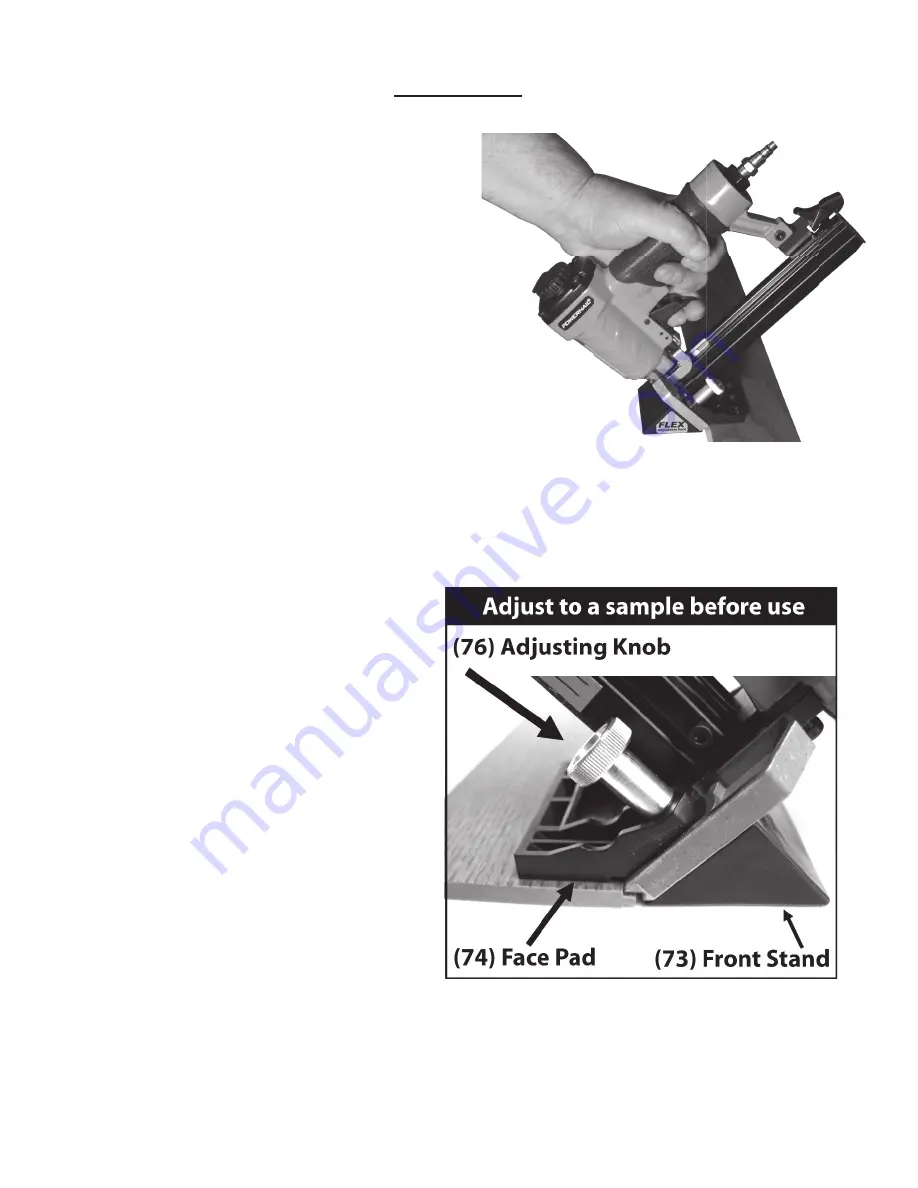

FOOT ADJUSTMENT / STAPLE LOCATION

Figure 1.

Loosen both adjusting knobs (76)

Hold stapler on sample piece of sample

fl ooring to be installed.

Adjust the face pad (74) so it lays fl at on

the fi nished surface of the fl ooring (Fig 1).

Lightly snug both adjusting knobs (76).

Push down on front stand (73) so it lays

fl at on the sub fl oor.

Tighten both adjusting knobs (76).

Test the adjustment by stapling down a

sample piece of fl oor

Readjust if necessary so that the staple

insertion point enters the top of the fl ooring

nail pocket.

OPERATION