34

Trouble Probable

Cause

Remedy

Blade cooled too rapidly after welding.

Replace blade, or have blade

annealed, or eliminate brittle part and

weld correctly.

Thrust bearing not properly

supporting blade, or guide post/side

bearings set too high allowing flex.

Check all guide bearings for correct

position and signs of wear. Adjust or

replace as needed.

Blade tensioned too tightly.

Reduce tension (see page 22).

Blade breaks close to

weld.

Blade overheated during welding.

Have blade annealed, or eliminate

brittle part and weld correctly.

Blade cooled too rapidly after welding.

Have blade annealed, or eliminate

brittle part and weld correctly.

Premature dulling of

saw teeth.

Blade “pitch” too fine.

Refer to blade selection chart. Use

blade with coarser pitch.

Feed pressure too light.

Increase feed pressure.

Cutting rate too low.

Increase feed pressure and cutting

rate.

Incorrect choice of blade.

Re-examine material. Select proper

blade from the chart.

Chipped tooth or foreign object

lodged in cut.

Stop the saw and remove lodged

particle. Replace blade if damaged.

Optional Accessories

1791217 ...... 6” Riser Block Kit

2042377 ...... Mobile Base for PWBS14-CS Band Saw

Summary of Contents for 1791216K

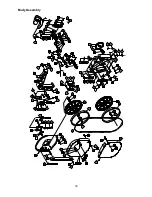

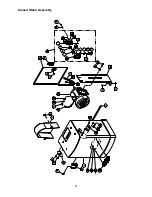

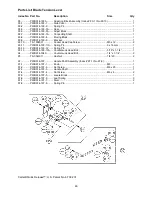

Page 39: ...39 Body Assembly...

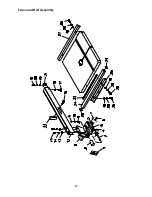

Page 41: ...41 Closed Stand Assembly...

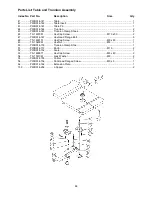

Page 43: ...43 Fence and Rail Assembly...