10

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

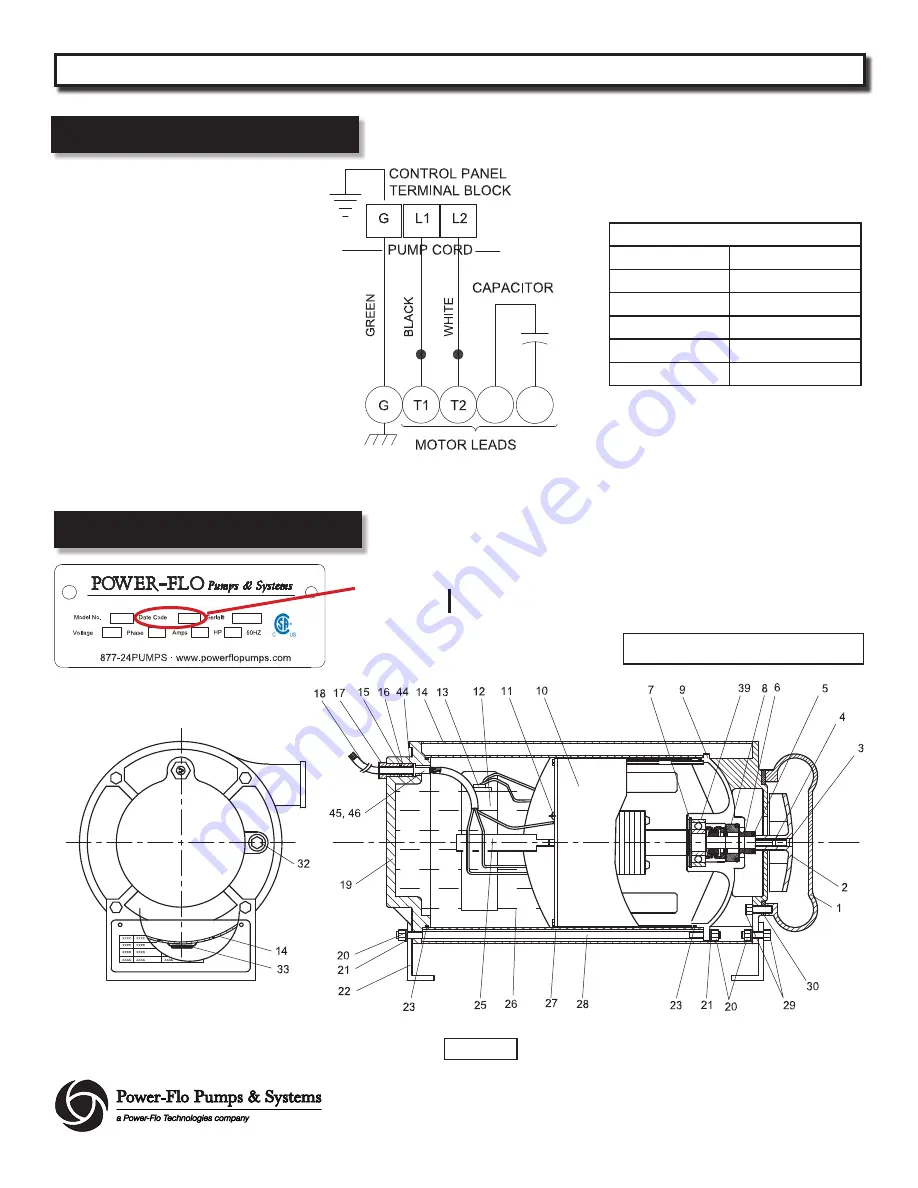

Power Cable Connection

Place gland nut (17), one friction ring

(12), grommet (15) onto cord and slide

cord through housing end piece (19).

Make wire connections using terminal

connectors (24). Place o-ring (23) into

groove on housing end piece (19) and

slide end piece onto housing tube (27)

being careful not to damage o-ring. Place

pump support (22) onto lower studs

(28) and place lockwashers (21) and hex

nuts (20) onto studs and tighten. Insert

grommet and friction ring into housing

end piece (19). Apply pipe sealant to

gland nut (17), screw into end piece and

torque gland nut to 17.5 ft. lbs to prevent

water leakage.

Service

For Repair Part Please supply: Model Number and MFG Date as shown on

Name Plate, and Part Description and Part Number as shown on Parts List.

Figure 3

Figure 2 - 115 & 230 Volt, 1Ph

POWER CABLE

MOTOR LEAD

Green (Ground)

Green

T1 - Black

Straight Connector

T2 - White

Straight Connector

Capacitor

Flag Connector

Capacitor

Flag Connector

Repair Parts - Bearing Design

For Units from Jan. 2011

PFU31, PFU51, PFU71, PFU102, PFU152, PFU202

Submersible Fountain Pumps

Date Code: G F

The second letter determens the year.

A thru E = 2007 - 2011

F and up = 2012 - and up