8

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

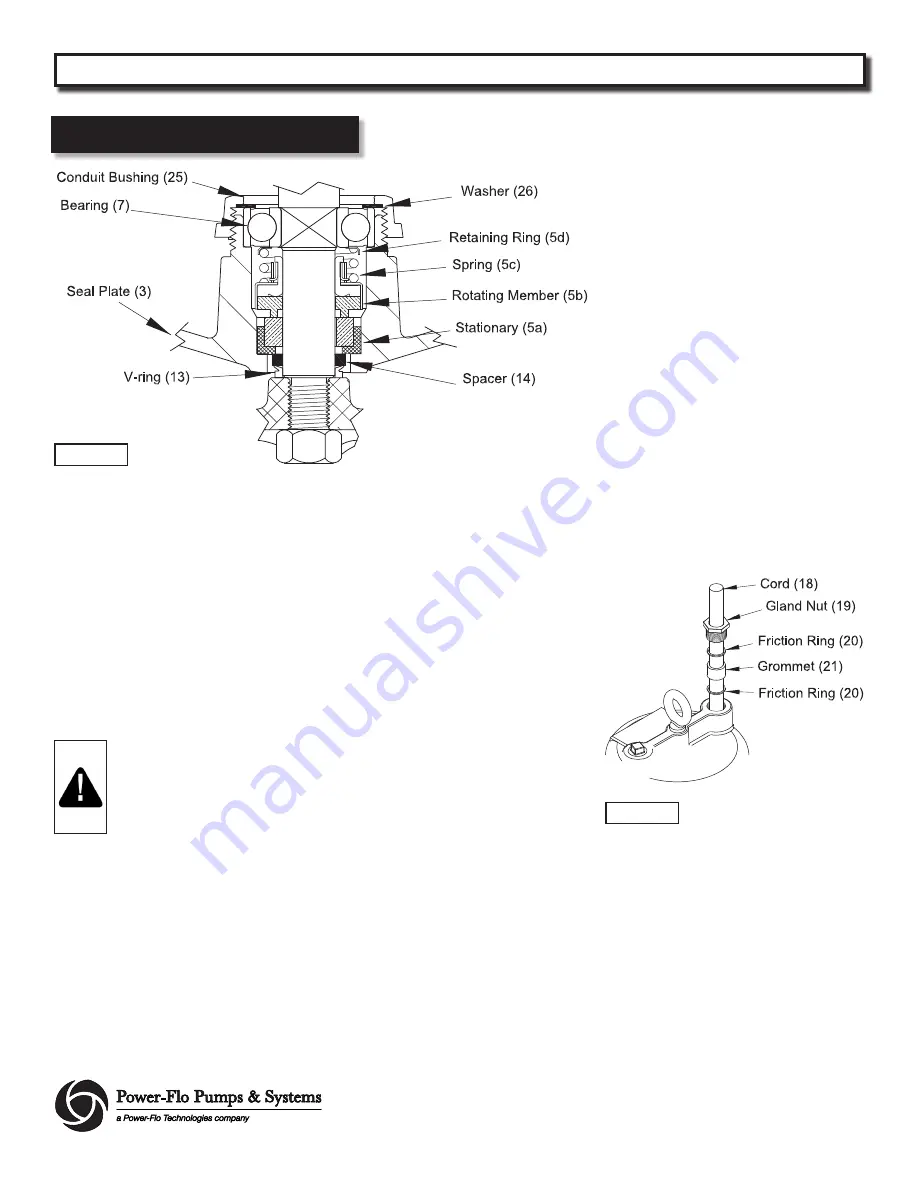

If replacing the seal, remove stationary

(5a) from seal plate (3) by prying out with

screw driver.

BEARING -

Examine bearing (7) and

replace if worn. Remove bearing (7) from

shaft using a wheel puller, if replacement

is required. The washer bushing (26)

and conduit bushing (25) can now be

removed.

REASSEMBLY

IMPORTANT! - All parts must be

clean before reassembly.

Handle seal parts with extreme

care. DO NOT damage lapped

surfaces.

To reassemble

-

clean seal cavity in seal

plate (3) and oil. Press seal’s (5) stationary

member (5a) firmly into seal plate (3),

using a seal tool or pipe. Nothing should

come in contact with the seal face except

the seal tool. Be sure the stationary is in

straight. Lightly oil

(Do not use grease)

shaft and inner surface of bellows.

Slide retaining ring (5d) and spring (5c)

over shaft and let rest on bearing. Lightly

oil

(Do not use grease)

shaft, bullet

and inner srface of bellows on rotating

member (5b). See Figure 3. With lapped

surface of rotating member (5b) facing

outward, slide over seal tool and unto

shaft, making sure spring (5c) is seated in

retaining ring (5d) and spring (5c) is lined

up on rotating member (5b) and not

cocked or resting on bellows tail.

Place conduit bushing (25) and washer

(26) onto shaft. Slide rotor/shaft (6) with

bearing (7) and seal (5) into seal plate

(3) until bearing (7) seats into seal plate.

Locate washer (26) into place on bearing

and tighten conduit bushing (25) onto

seal plate (3). Place stator (6) over rotor

(6), lining up motor bolts with holes in

seal plate (3). Position capacitor (29) on

motor with clamp (30) and reconnect

capacitor leads. Torque motor bolts to

17 in-lbs. Set square ring (11) in grove on

seal plate (3).

Lower motor housing (4) down onto

seal plate (3) while aligning holes and

stringing motor leads through the cord

entry bore. Place socket head screws (15)

through seal plate (3) into housing (4)

and torque to 60 in-lbs. Reconnect motor

leads, as shown in Figure 5.

Power Cable Connection

Check power cord (18) for cracks or

damage and replace if required. Insert

one washer (20), grommet (21), washer

(20) into motor housing (4). Apply pipe

sealant to gland nut (19) and screw into

motor housing (4). Torque gland nut to

(19) to 15 ft. lbs. to prevent water leakage

(See Figure 4). Refill the cooling oil and

replace pipe plug (16).

Insert spacer (14) and v-ring (13) into seal

plate (3) and reassemble remaining parts

per “Impeller, V-ring and Volute” section on

page 7.

Service

PFEH

Submersible Effluent Pumps

Figure 3

Figure 4