8

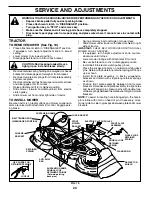

INSTALL MOWER AND DRIVE BELT

(See Figs. 6 and 7)

Be sure tractor is on level surface and mower suspension

arms are raised with attachment lift control. Engage park-

ing brake.

• Cut and remove ties securing anti-sway bar and belts.

Swing anti-sway bar to left side of mower deck.

• Slide mower under tractor with defl ector shield to right

side of tractor.

IMPORTANT:

Check belt for proper routing in all mower

pulley grooves.

• If equipped, turn height ad just ment knob coun

ter -

clock wise until it stops.

ASSEMBLY

FIG. 5

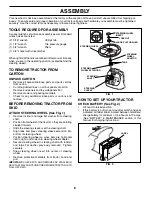

TO ATTACH NOSE ROLLER (See Fig. 5)

• Assemble brackets "A" and "B" to the inside of mower

mounting brack ets as shown. Tighten securely.

NOTE:

Be sure bracket tabs are po si tioned in tab holes

in mower brackets.

• Position nose roller between brackets and install rod

and retainer spring.

02612

NOSE

ROLLER

HEX

BOLT

"A"

BRACKET

LOCK

NUT

TAB

HOLE

RETAINER SPRING

ROD

"B"

BRACKET

• Lower mower linkage with attachment lift control.

• Be sure belt tension rod is in dis en gaged position.

Install belt into electric clutch pulley groove.

• Place the suspension arms on outward pointing deck

pins. Retain with double loop re tain er spring with loops

up as shown.

• Install front plate assembly to tractor suspension

brack ets and retain with single loop retainer springs

as shown.

• Position front plate assembly between front mower

brackets. Raise deck and plate assembly to align holes

and insert fl anged pins. Secure pins with double loop

retainer springs between the plate assembly and mower

brackets.

NOTE:

To assist in locating hole in fl anged pin, the hole in

pin is inline with notch on head of pin. If necessary, move

mower side-to-side to give space between plate and mower

brackets.

IMPORTANT:

Check belt for proper routing in all mower

pulley grooves. Engage belt tension rod by pushing rod

into locking bracket.

• Engage belt tension rod by pushing rod into locking

bracket.

CAUTION: Belt tension rod is spring

loaded. Have a tight grip on rod and

engage slowly.

• Connect anti-sway bar to chassis bracket under left

foot rest and retain with double loop retainer spring.

• If equipped, turn height adjustment knob clock wise to

remove slack from mower sus pen sion.

• Raise deck to highest position.

• Adjust gauge wheels before op er at ing mower as shown

in the Operation section of this manual.

02510

ANTI-SWAY

BAR

SINGLE LOOP

RE TAIN ER SPRINGS

GAUGE WHEEL

SUS PEN SION ARMS

DOUBLE LOOP

RE TAIN ER SPRING

FRONT SUS PEN SION

BRACKETS

FRONT PLATE

AS SEM BLY

CHAS SIS

BRACKET

DOUBLE LOOP RETAINER

SPRING (OUTWARD

POINT ING DECK PINS)

ELECTRIC CLUTCH

PULLEY

DE FLEC TOR SHIELD

USE PLIERS FOR

RETAINER SPRINGS

LOOP UP

FRONT

MOWER

BRACKET

BELT TENSION ROD

(DISENGAGED POSITION)

LOCK BRACKET

FLANGED

PIN

DOUBLE LOOP

RE TAIN ER SPRING

FIG. 6