18

STORAGE

Immediately prepare your snow thrower for storage at the

end of the season or if the unit will not be used for 30 days

or more.

WARNING: Never store the snow

thrower with gaso line in the tank in side

a build ing where fumes may reach an

open fl ame, spark or pilot light as on a

fur nace, water heater, clothes dryer or

gas ap pli ance. Allow the engine to cool

be fore storing in any enclosure.

SNOW THROWER

When snow thrower is to be stored for a period of time,

clean it thor oughly, re move all dirt, grease, leaves, etc.

Store in a clean, dry area.

1. Clean entire snow thrower (See “CLEANING” in the

Main te nance section of this manual).

2. Inspect and replace belts, if necessary (See “TO RE-

PLACE BELTS” in the Service and Adjustments sec tion

of this manual).

3. Lubricate as shown in the Main te nance sec tion of this

man u al.

4. Be sure that all nuts, bolts, screws, and pins are securely

fas tened. Inspect moving parts for damage, breakage

and wear. Replace if nec es sary.

5. Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

ENGINE

See engine manual.

FUEL SYS TEM

IMPORTANT

: It is important to prevent gum deposits from

forming in essential fuel system parts such as carburetor,

fuel hose, or tank during storage. Also, alcohol blended fuels

(called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of

an engine while in storage.

1. Drain the fuel tank.

2. Start the engine and let it run until the fuel lines and

car bu re tor are empty.

• Never use engine or carburetor cleaner prod ucts in the

fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE:

Fuel stabilizer is an acceptable alternative in min-

i miz ing the formation of fuel gum deposits during stor age.

Add stabilizer to gasoline in fuel tank or storage container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 min utes after adding stabilizer to

allow the stabilizer to reach the carburetor. Do not drain the

gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace with clean en-

gine oil. (See “ENGINE” in the Maintenance section of

this man ual).

CYLINDER

1. Remove spark plug.

2. Pour one ounce (30 ml) of oil through spark plug hole

into cylinder.

3. Pull recoil starter handle slowly a few times to dis trib ute

oil.

4. Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your snow thrower indoors and cover

it to protect it from dust and dirt.

• Cover your snow thrower with a suitable pro tec tive cover

that does not retain moisture. Do not use plastic. Plastic

cannot breathe, which allows con den sa tion to form and

will cause your snow thrower to rust.

IMPORTANT

: Never cover snow thrower while engine/

exhaust area is still warm.

NOTE:

To seal punctures or prevent fl at tires due to slow

leaks, tire sealant may be purchased from your local parts

dealer. Tire sealant also prevents tire dry rot and cor ro sion.

ENGINE

See engine manual.

CARBURETOR

Your carburetor is not adjustable. Engine performance

should not be affected at altitudes up to 7,000 feet (2,134

meters). If your engine does not operate properly due to

suspected carburetor problems, take your snow thrower to

a qualifi ed service center.

ENGINE SPEED

Never tamper with the engine governor, which is factory set

for proper engine speed. Overspeeding the engine above

the factory high speed setting can be dangerous and will

void the warranty. If you think the engine-governed high

speed needs adjusting, contact a qualifi ed service center,

which has proper equipment and experience to make any

necessary ad just ments.

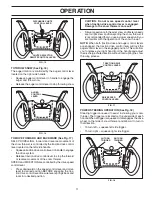

TO REMOVE WHEELS (See Fig. 24)

• Remove the klik pin and remove wheel from axle.

IMPORTANT:

When installing wheel, be sure to use the in-

nermost hole in axle and the wheel hub hole. To dis en gage

drive system from the wheels (for pushing or trans port ing

the snow thrower), remove klik pin from wheel hub and

insert pin into the outermost hole in axle only.

INNER

HOLE

KLIK PIN

OUTER HOLE

WHEEL HUB

WHEEL

FIG. 24