24

intelligently applied technology

© Baxi Heating UK Limited 2005

6.1 Commission the Water, Electrical and Gas

Systems

Water

The system should be cold flushed. After re-filling,

all air must be vented from the system before the

boiler is commissioned.

On Sealed Systems, manually test the safety valve

and fill until the pressure gauge registers 1.5 bar.

Electrical

Ensure that the preliminary electrical safety checks

detailed on Page 20 have been carried out.

Gas

The whole of the gas installation including the

meter must be checked for soundness and purged

according to in GB BS 6891 and in IE I.S. 813

“Domestic Gas Installations”.

6.2 Commission the Boiler

Ensure the top cover and door are correctly

fitted.

1. Ensure that the main electricity supply is ‘On’, the

‘Mains On’ (Green) light will flash.

2. Ensure that the main gas supply is turned ‘On’ and

that the boiler gas service cock is in the ‘On’

position.

3. Check that the programmer and any other external

controls, if fitted, are in an ‘On’ position and calling

for heat.

4. Turn the temperature control knob to its maximum

setting, the ‘Burner On’ (Green) light will flash and

after several seconds, the burner will light

automatically.

5. When the burner flame has established, the ‘Burner

On’ (Green) light will be on and flames will be visible

through the sight glass.

6. With the burner running, check the boiler for gas

soundness using leak detection fluid.

7. Check that the gas supply pressure, burner

pressure and gas rate are correct. See data label

or refer to Page 6.

If adjustment of the burner pressure is required

follow Section 9.4.

8. Check that the burner flames are blue and stable.

9. Turn the temperature control knob to ( ) position

and check that the burner shuts down.

10. Remove the pressure gauge, re-fit the screws and

check for gas soundness.

11. Re-fit the controls cover assembly and secure with

the screws previously removed.

6.3 Flush the system

1. Drain the system whilst still hot.

2. Re-fill, vent the system, make a final check for

water soundness and add a suitable inhibitor.

3. Complete any labels supplied with the inhibitor and

attach to the boiler for future reference.

4. Set the system flow rate to give the required

temperature rise. Set the bypass flow rate.

5. On sealed systems fill until the pressure gauge

registers 1.5 bar. Set the pressure gauge pointer to

the system design pressure.

If the boiler fails to light

After five attempts (possibly due to air in the gas

supply) it will lockout and the ‘Lockout’ (Red) light will

be on.

To reset - Turn the temperature control knob to ( )

position. Wait until the ‘Lockout’ (Red) light switches

off. Turn the temperature control knob back to the

required setting. The boiler should reset and return to

normal operation.

If the boiler fails to operate

Check for fault or lockout codes on the control display

and refer to one or a combination of the following:-

User Operating label on the boiler. Wiring Diagram,

Control Sequence and Fault Finding sections in these

instructions.

6. Commissioning

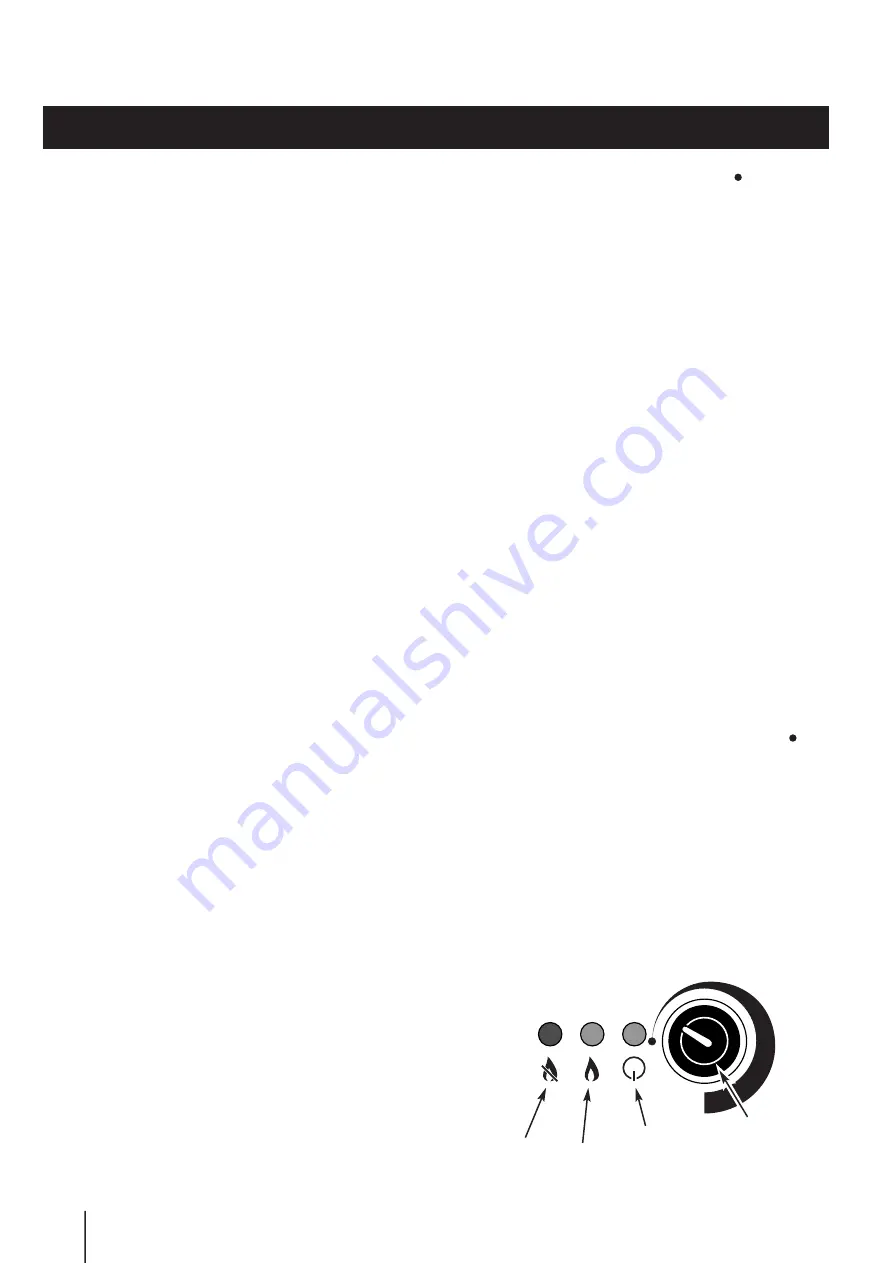

Mains On

(Green)

Temperature

Control Knob

Burner On

(Green)

Lockout

(Red)

Fig. 21