Part 13

resolve the auto cutter problems per description in next item and then come

back to deal with the paper jam.

Never force open the top hood.

Please also

clear away any contaminants accumulated in the cutter track above the thermal

elements.

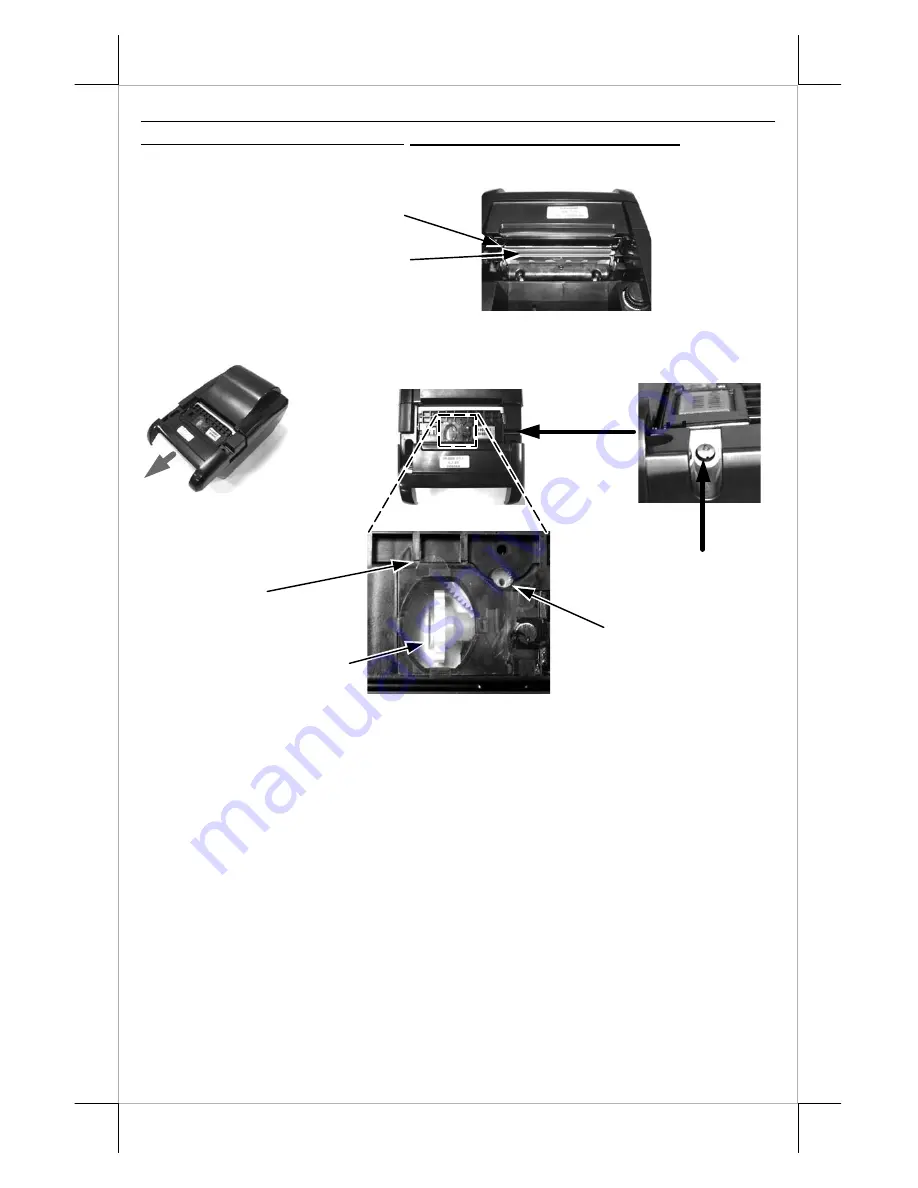

Auto Cutter Problems

In case any foreign materials like a staple or paper clip or excessive

paper scraps fall into the auto cutter mechanism the auto cutter may lock up

and so does the print hood. In such case, please pull the cutter cover forward to

expose the cutter adjustment area. Apply some mechanical assistance in below

procedures to help resetting the cutter blade back to its home position. Please

lift up a transparent protective cover over the adjustment wheel with the printer

powered off. Turn this wheel downward for 4 or 5 strokes. Close the cutter

cover back and turn the printer power on to see if the auto cutter lock up

problem is resolved.

If the problem is not automatically resolved by above procedures,

please power off the printer and open the cutter cover again. Check in the

alignment window while turning the gear downward as above or with a small

Phillips screwdriver at the right side of the cutter mechanism. When the cutter

blade returns to its standard position, a hole in the white plastic gear will show

up in the window as illustrated in detailed picture above. Close the cutter cover

Auto Cutter Track

Thermal Elements

Open Cutter Cover

when hood locked

Lift transparent

protective foil

Alignment window

Adjustment area detailed below

Use screwdriver

Turn the adjustment wheel

downward for few strokes