Air Compressor Pump:

To compress air,

the piston moves up and down in the

cylinder. On the downstroke, air is drawn

in through the intake valves. The exhaust

valves remain closed. On the upstroke of

the piston, air is compressed. The intake

valves close and compressed air is forced

out through the exhaust valves.

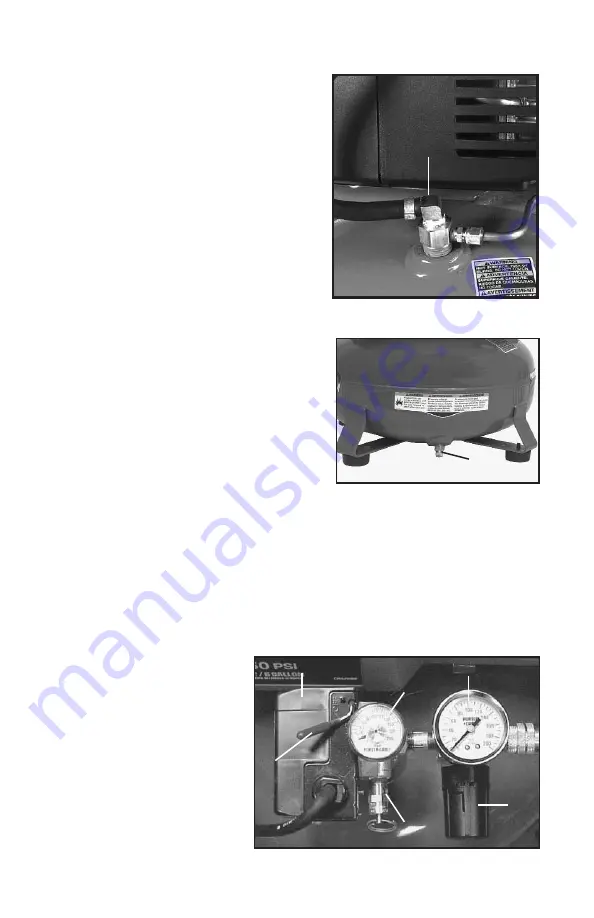

Check Valve (B) Fig. 1:

When the air

compressor is operating, the check valve

is “open”, allowing compressed air to

enter the air tank. When the air

compressor reaches “cut-out” pressure,

the check valve “closes”, allowing air

pressure to remain inside the air tank.

ON/AUTO-OFF Switch (C) Fig. 3:

Turn

this switch ON to provide power to the

automatic pressure switch and OFF to

remove power at the end of each use.

Pressure Switch (D) Fig. 3:

The

pressure switch automatically starts the

motor when the tank pressure drops

below the factory set “cut-in” pressure. It

stops the motor when the air tank

pressure reaches the factory set “cut-

out” pressure.

Regulator (E) Fig. 3:

The air pressure coming from the air tank is controlled by

the regulator. Turn the regulator knob clockwise to increase pressure and

counterclockwise to decrease pressure. To avoid minor readjustment after

making a change in pressure setting, always approach the desired pressure

from a lower pressure. When reducing from a higher to a lower setting, first

reduce to pressure less than that desired, then bring it up to the desired

pressure. Depending on the air requirements of each particular accessory, the

outlet regulated air pressure may have to be adjusted while operating the

accessory.

Outlet Pressure Gauge (F)

Fig. 3:

The outlet pressure

gauge indicates the air

pressure available at the

outlet side of the regulator.

This pressure is controlled

by the regulator and is

always less than or equal to

the tank pressure. See

“Operating Procedures”.

7

E

DESCRIPTION OF OPERATION

Fig. 1

Fig. 2

Fig. 3

K

J

F

C

B

G

D